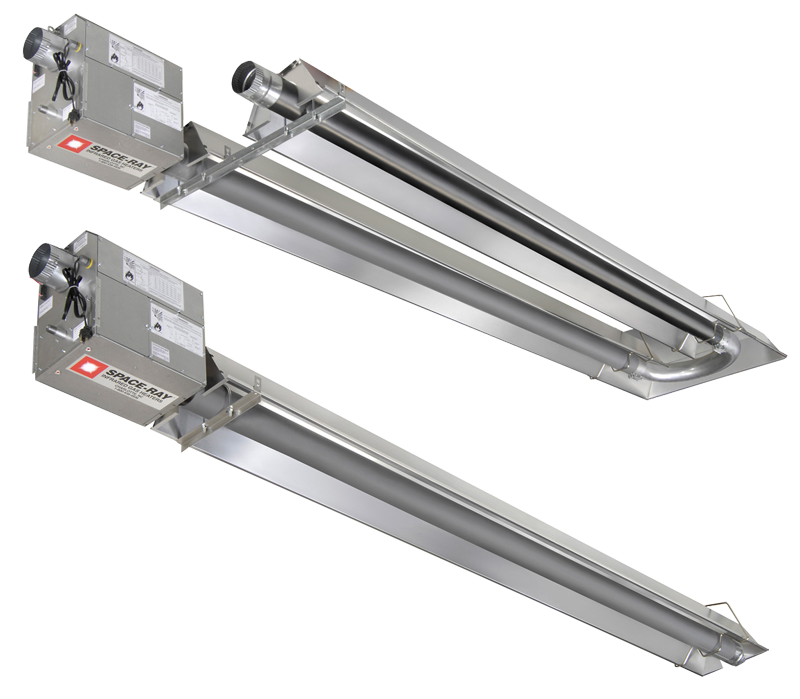

PTS Series

| MODEL* | SINGLE STAGE BTH / HR INPUT | TWO STAGE | MINIMUM MOUNTING HEIGHT** | |

| BTU / HR HIGH INPUT | BTU / HR LOW INPUT | |||

|

PTS 40

|

40,000 | 40,000 | 25,000 | 10′ |

|

PTS 50

|

50,000 | 50,000 | 30,000 | 11′ |

|

PTS 60

|

60,000 | 60,000 | 40,000 | 12′ |

|

PTS 75

|

75,000 | 75,000 | 50,000 | 13′ |

|

PTS 100

|

100,000 | 100,000 | 65,000 | 14′ |

|

PTS 125

|

125,000 | 125,000 | 80,000 | 14′ |

|

PTS 150

|

150,000 | 150,000 | 100,000 | 15′ |

|

PTS 175

|

175,000 | 175,000 | 110,000 | 16′ |

|

PTS 200

|

200,000 | 200,000 | 125,000 | 18′ |

* Indicate model number based on Btu/hr input (e.g. 100,000 Btu/hr), emitter length (e.g. 30 ft.) . Control suffix (e.g. Natural Gas single stage input ) . The unit selection would be PTS100-30-N5. See Dimension Tab for all allowable Emitter Tube Lengths.

ALC Option for Harsh environments: All calorized aluminized steel (ALC) radiant emitter tubes for ALC option the model number would be PTS100- 40-ALC-N5. Note: for car washes, dairy barns, greenhouses, swimming pools, waste water treatment plants, and other high humidity / corrosive environments, the ALC option with all calorized aluminized tubes is recommended.

CNG Series for CNG & LNG Service Facilities:They can be installed in compliance with NFPA 30A Motor Fuel Dispensing Facilities and Repair Garage Code. CNG series is limited to 40,000 through 75,000 Btu/hr.Indicate model number based on Btu/hr input (e.g., 75,000 Btu/hr), total emitter length, (e.g., 40 feet) and gas type (e.g., natural gas single stage input).The unit’sCNG selection for a straight tube would be PTS75-CNG-40-N5 and for a U-tube would be PTU75-CNG-40-N5.

** Minimum recommended mounting heights are intended as a guide only, as heaters may be mounted at various heights and angles. Mount heaters as high as possible. Minimums are shown as a guideline for human comfort and uniform enrgy distribution for complete building applications. Please consult your Space-Ray Representative for a detailed analysis of your particular heating requirements..

| Control Suffix | Type of Gas | Control Option Description | |||||

| N5/ L5 | Natural / Propane | Single Stage Gas Valve- Single Stage Input | |||||

| N7 / L7 | Natural / Propane | Two Stage Gas Valve- Modulating Input – High/Low Fire | |||||

Floor Level Coverage – The above chart may be used as a guideline for primary radiation, i.e. the infrared pattern directly below the heater. In a well-insulated building, only 50% of the floor needs to be covered by the primary radiant pattern. Please be aware that the radiant energy generated by infrared heaters is not limited to the primary radiant pattern. There is additional radiant energy that is absorbed outside the primary area, a secondary radiant pattern. Since concrete is a very good conductor of heat, a reasonably uniform floor temperature eventually will be reached. The amount of time it takes to reach “thermal equilibrium” is in direct correlation to the distance between the heaters.

Learn More >>

PTU Series

| MODEL* | SINGLE STAGE BTH / HR INPUT | TWO STAGE | MINIMUM MOUNTING HEIGHT** | |

| BTU / HR HIGH INPUT | BTU / HR LOW INPUT | |||

|

PTU 40

|

40,000 | 40,000 | 25,000 | 10′ |

|

PTU 50

|

50,000 | 50,000 | 30,000 | 11′ |

|

PTU 60

|

60,000 | 60,000 | 40,000 | 12′ |

|

PTU 75

|

75,000 | 75,000 | 50,000 | 13′ |

|

PTU 100

|

100,000 | 100,000 | 65,000 | 14′ |

|

PTU 125

|

125,000 | 125,000 | 80,000 | 14′ |

|

PTU 150

|

150,000 | 150,000 | 100,000 | 15′ |

|

PTU 175

|

175,000 | 175,000 | 110,000 | 16′ |

|

PTU 200

|

200,000 | 200,000 | 125,000 | 18′ |

* Indicate model number based on Btu/hr input (e.g. 100,000 Btu/hr), emitter length (e.g. 30 ft.) . Control suffix (e.g. Natural Gas single stage input ) . The unit selection would be LTS100-30-N5. See Dimensions Tab for all allowable Emitter Tube Lengths.

** Minimum recommended mounting heights are intended as a guide only, as heaters may be mounted at various heights and angles. Mount heaters as high as possible. Minimums are shown as a guideline for human comfort and uniform energy distribution for complete building applications. Please consult your Space-Ray Representative for a detailed analysis of your particular heating requirements.

| Control Suffix | Type of Gas | Control Option Description | |||||

| N5/ L5 | Natural / Propane | Single Stage Gas Valve- Single Stage Input | |||||

| N7 / L7 | Natural / Propane | Two Stage Gas Valve- Modulating Input – High/Low Fire | |||||

Floor Level Coverage – The above chart may be used as a guideline for primary radiation, i.e. the infrared pattern directly below the heater. In a well-insulated building, only 50% of the floor needs to be covered by the primary radiant pattern. Please be aware that the radiant energy generated by infrared heaters is not limited to the primary radiant pattern. There is additional radiant energy that is absorbed outside the primary area, a secondary radiant pattern. Since concrete is a very good conductor of heat, a reasonably uniform floor temperature eventually will be reached. The amount of time it takes to reach “thermal equilibrium” is in direct correlation to the distance between the heaters.

Learn More >>

Push Through System (positive presure)

- Products of combustion are pushed through the combustion chamber

- Tube Integrity Safety System (TISS)

- No draft hoods, totally enclosed combustion chamber

- Blower motor totally enclosed in the burner box, ideal for applications where minimal noise (less than 50dB) is desired

- Heavy duty permanently lubricated ball bearing blower motor for maintenance-free operation

- Tubes & Reflectors are bulk shipped for easy field assembly

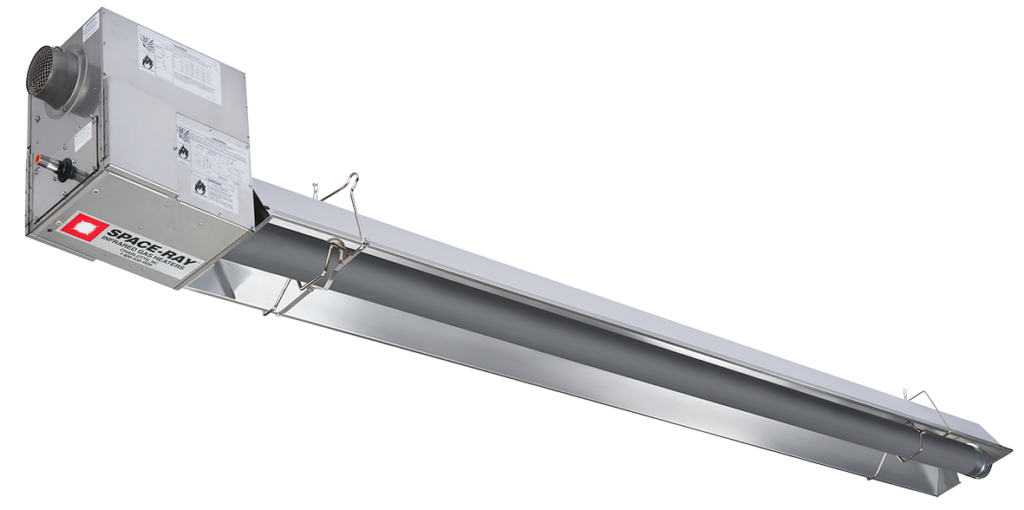

Burner System

- Heavy duty cast iron burner

- 10- year limited warranty on burner

- Inside or optional outside air for combustion

- Up to 40 ft. outside combustion air duct capability

- Standard 4″ combustion air collar

- Reliable direct spark ignition system and 100% gas shut-off safety control

- Pre-purge and post-purge function

- State-of-the-art step opening redundant combination gas valve for quiet ignition and added safety

- Diaphragm air switch for proof of venting before gas flow and ignition

- Diagnostic monitoring light system

- Burner inspection sight glass

- Line voltage or external 24V thermostat connection

- 36″ stainless steel flexible gas connector included with burner box

Radiant Emitter Tube System

- 4″ O. D. heavy-duty calorized aluminized steel or alumi-therm steel combustion chamber (10 feet) and heavy duty hot-rolled steel radiant emitter tubes

- Optional calorized aluminized steel (ALC Option) radiant emitter tubes.

- 3-year limited warranty on the emitter tubes

- Suitable for horizontal or angle mounting up to 45°

- Optional 90° elbows

- Up to 40 feet sidewall vent capacity

- Optional 5′ or 10′ body extension packages

ALC Option: All calorized aluminized steel (ALC) radiant emitter tubes– for ALC option the model number would be PTS100-40-ALC-N5. Note: for Carwashes, Dairy Barns, Greenhouses, Swimming Pools, Waste Water Treatment Plants, and other high humidity/corrosive environments, ALC option with all calorized aluminized tubes is recommended. Calorized aluminized steel emitter tubes provide long life, corrosion resistance, and high radiant efficiency — will not flake or peel. Ideal for high humidity/corrosive environments.

Learn More about Calorized Aluminized Steel Emitter Tubes (PDF).

Reflector System

- Highly efficient aluminum reflectors with reflectivity rating of 97.5%

- Optional end, corner, side and U-bend reflectors

- Optional decorative grille

- Individual reflectors can be rotated up to 45° to direct heat where needed

- Easy-to-use mounting brackets & wire hangers

Other

- CSA Certified according to ANSI Z83.20 and CSA 2.34. NOT Certified for Residential Use

| MODEL | INPUT BTU/HR |

TOTAL TUBE LENGTH (FT) |

OVERALL DIMENSION “L” (FT) |

REFLECTOR WIDTH “W” (IN) |

REFLECTOR HEIGHT “H” (IN) |

SHIPPING WEIGHT Lbs.** |

| PTS40-10 | 40,000 | 10′ | 11′ 2″ | 13″ | 6″ | 80 |

| PTS40-20 | 40,000 | 20′ | 21′ 2″ | 13″ | 6″ | 130 |

| PTS50-20 | 50,000 | 20′ | 21′ 2″ | 13″ | 6″ | 130 |

| PTS75-20 | 75,000 | 20′ | 21′ 2″ | 13″ | 6″ | 130 |

| PTS50-30 | 50,000 | 30′ | 31′ 2″ | 13″ | 6″ | 166 |

| PTS75-30 | 75,000 | 30′ | 31′ 2″ | 13″ | 6″ | 166 |

| PTS100-30 | 100,000 | 30′ | 31′ 2″ | 13″ | 6″ | 166 |

| PTS125-30 | 125,000 | 30′ | 31′ 2″ | 13″ | 6″ | 166 |

| PTS50-40 | 50,000 | 40′ | 41′ 2″ | 13″ | 6″ | 202 |

| PTS75-40 | 75,000 | 40′ | 41′ 2″ | 13″ | 6″ | 202 |

| PTS100-40 | 100,000 | 40′ | 41′ 2″ | 13″ | 6″ | 202 |

| PTS125-40 | 125,000 | 40′ | 41′ 2″ | 13″ | 6″ | 202 |

| PTS150-40 | 150,000 | 40′ | 41′ 2″ | 13″ | 6″ | 202 |

| PTS175-40 | 175,000 | 40′ | 41′ 2″ | 13″ | 6″ | 202 |

| PTS100-50 | 100,000 | 50′ | 51′ 2″ | 13″ | 6″ | 238 |

| PTS125-50 | 125,000 | 50′ | 51′ 2″ | 13″ | 6″ | 238 |

| PTS150-50 | 150,000 | 50′ | 51′ 2″ | 13″ | 6″ | 238 |

| PTS175-50 | 175,000 | 50′ | 51′ 2″ | 13″ | 6″ | 238 |

| PTS200-50 | 200,000 | 50′ | 51′ 2″ | 13″ | 6″ | 238 |

| PTS125-60 | 125,000 | 60′ | 61′ 2″ | 13″ | 6″ | 292 |

| PTS150-60 | 150,000 | 60′ | 61′ 2″ | 13″ | 6″ | 292 |

| PTS175-60 | 175,000 | 60′ | 61′ 2″ | 13″ | 6″ | 292 |

| PTS200-60 | 200,000 | 60′ | 61′ 2″ | 13″ | 6″ | 292 |

| PTS175-70 | 175,000 | 70′ | 71′ 2″ | 13″ | 6″ | 328 |

| PTS200-70 | 200,000 | 70′ | 71′ 2″ | 13″ | 6″ | 328 |

** Hanging weight is 80% of shipping weight

| MODEL | INPUT BTU/HR |

TOTAL TUBE LENGTH (FT) |

OVERALL DIMENSION “L” (FT) |

REFLECTOR WIDTH “W” (IN) |

REFLECTOR HEIGHT “H” (IN) |

SHIPPING WEIGHT Lbs.** |

| PTU40-20 | 40,000 | 20′ | 12′ 5″ | 31″ | 6″ | 130 |

| PTU50-20 | 50,000 | 20′ | 12′ 5″ | 31″ | 6″ | 130 |

| PTU75-20 | 75,000 | 20′ | 12′ 5″ | 31″ | 6″ | 130 |

| PTU50-30 | 50,000 | 30′ | 17′ 5″ | 31″ | 6″ | 166 |

| PTU75-30 | 75,000 | 30′ | 17′ 5″ | 31″ | 6″ | 166 |

| PTU100-30 | 100,000 | 30′ | 17′ 5″ | 31″ | 6″ | 166 |

| PTU125-30 | 125,000 | 30′ | 17′ 5″ | 31″ | 6″ | 166 |

| PTU50-40 | 50,000 | 40′ | 22′ 5″ | 31″ | 6″ | 202 |

| PTU75-40 | 75,000 | 40′ | 22′ 5″ | 31″ | 6″ | 202 |

| PTU100-40 | 100,000 | 40′ | 22′ 5″ | 31″ | 6″ | 202 |

| PTU125-40 | 125,000 | 40′ | 22′ 5″ | 31″ | 6″ | 202 |

| PTU150-40 | 150,000 | 40′ | 22′ 5″ | 31″ | 6″ | 202 |

| PTU175-40 | 175,000 | 40′ | 22′ 5″ | 31″ | 6″ | 202 |

| PTU100-50 | 100,000 | 50′ | 27′ 5″ | 31″ | 6″ | 238 |

| PTU125-50 | 125,000 | 50′ | 27′ 5″ | 31″ | 6″ | 238 |

| PTU150-50 | 150,000 | 50′ | 27′ 5″ | 31″ | 6″ | 238 |

| PTU175-50 | 175,000 | 50′ | 27′ 5″ | 31″ | 6″ | 238 |

| PTU200-50 | 200,000 | 50′ | 27′ 5″ | 31″ | 6″ | 238 |

| PTU125-60 | 125,000 | 60′ | 32′ 5″ | 31″ | 6″ | 238 |

| PTU150-60 | 150,000 | 60′ | 32′ 5″ | 31″ | 6″ | 292 |

| PTU175-60 | 175,000 | 60′ | 32′ 5″ | 31″ | 6″ | 292 |

| PTU200-60 | 200,000 | 60′ | 32′ 5″ | 31″ | 6″ | 292 |

| PTU175-70 | 175,000 | 70′ | 37′ 5″ | 31″ | 6″ | 328 |

| PTU200-70 | 200,000 | 70′ | 37′ 5″ | 31″ | 6″ | 328 |

** Hanging weight is 80% of shipping weight

| GAS TYPE | BURNER PRESSURE | MINIMUM SUPPLY PRESSURE |

MAXIMUM SUPPLY PRESSURE |

VOLTAGE | AMPS | IGNITION TYPE |

| NATURAL | 3.5″ W.C. | 5″ W.C.* | 14″ W.C. | 120 VAC | 1.8 | DIRECT SPARK |

| PROPANE | 10″ W.C. | 11″ W.C.** | 14″ W.C. | 60 HZ |

NOTE: For all installations higher than 2000 ft. above sea level please consult the factory regarding recommended derating of heaters.

* 7″ W.C. for Models 150-200

** 12″ W.C. for Models 200

| MODEL | SIDE | CEILING* | BELOW | ENDS | FRONT | REAR(45° angle) |

| PTS/U 40 | 22″ | 6″ | 52″ | 15″ | 40″ | 12″ |

| PTS/U 50 | 22″ | 6″ | 56″ | 15″ | 48″ | 12″ |

| PTS/U 75 | 22″ | 6″ | 60″ | 15″ | 52″ | 12″ |

| PTS/U 100 | 28″ | 6″ | 70″ | 15″ | 58″ | 12″ |

| PTS/U 125 | 28″ | 6″ | 76″ | 20″ | 66″ | 12″ |

| PTS/U 150 | 34″ | 6″ | 81″ | 20″ | 70″ | 12″ |

| PTS/U 175 | 38″ | 6″ | 86″ | 20″ | 75″ | 12″ |

| PTS/U 200 | 42″ | 6″ | 93″ | 20″ | 80″ | 12″ |

NOTE:The clearances specified above must be maintained to combustibles and other materials that may be damaged by temperatures 90°F above ambient temperature. Clearances to combustibles are posted on the reflector near the control end of the heater. In locations used for storage of combustible materials where they may be stacked below the heater, NFPA 54 requires that the installer must post signs that will “specify the maximum permissible stacking height to maintain the required clearances from the heater to combustibles”.

* When used indirect vented, clearance to CEILING must be: 12” for PTS/U (50-75) and 18” for PTS/U (100-200). If optional corner and u-bend reflectors are not used, the clearance must be 18”.

** Maximum clearance below reduces by 50% once you are 25ft. downstream from the burner box. Note: Consult Factory if reduced clearances are required

VENTING REQUIREMENTS

Heaters can be common vented, vented or indirect vented. A vented installation must be vented outside the building with a flue pipe. An indirect vented installation requires a minimum ventilation flow of 4 CFM per 1000 BTU/hour of total installed heater capacity on natural gas by either gravity or power ventilation (4.18 CFM per 1000 BTU/hour on propane).

INSTALLATION REQUIREMENTS

Installation and service must be performed by a licensed contractor. The installation must conform to written Instalation & Operating Instructions and local codes. In the absence of local codes, the installation must conform with the National Fuel Gas code, ANSI Z223.1 (latest edition also known as NFPA54) or GCA B149 (latest edition) installation codes. These codes are available from the National Fire Protection Association, Inc., Batterymarch Park, Quincy, MA 02269 or the Canadian Gas Association, 55 Scarsdale Road, Toronto, Ontario M3B 2R3, CANADA.

FOR YOUR SAFETY

Operate infrared heaters with proper care and observe all safety precautions. Carefully follow printed installation, operating and cleaning instructions furnished with the heater. Do not store gasoline or combustible products in the vicinity of the heater. Do not touch the heater or the tubes while the heater is in operation. Adequate ventilation must always be provided in accordance with codes.

Deflector Kit

The Deflector Kit (Part # 43482000) is used to reduce clearances to combustibles below the heater. Details on Deflector Kit (PDF)

Side Reflector Kits

Side Reflector kits can be used to reduce the clearences to combustibles to the side of the heater. They are available as single side reflector or 2-side reflector.

Side Reflector Installation info (PDF)

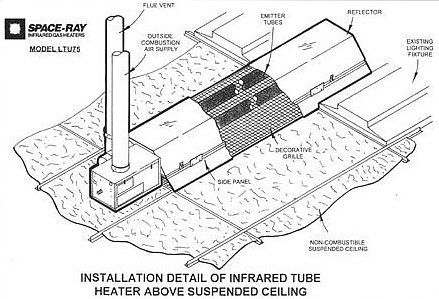

Decorative Grille Kits

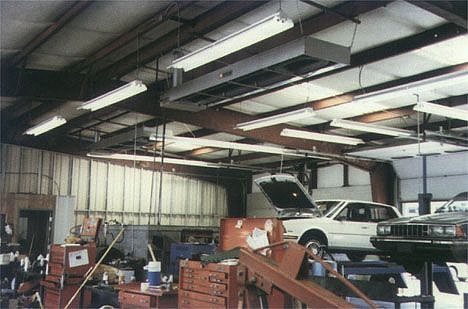

The heaters can be installed over non-combustible suspended ceilings with the use of aluminum decorative grilles. Decorative Grille Installation Instructions (PDF)

90 Degree Elbow Package Kit

Heaters can be installed in various configurations- L Shape, Z Shape etc. using 90 degree elbows. See I & O’s for typical layouts. 90 Degree Elbow Accessory Package Kit (Part #43208010) comes with the required couplings and hardware. PTS Series Only.

Corner Reflector Package Kit

Used with 90 Degree Elbow Package Kit. It maintains the clearences to combustibles above the reflector and maximizes the emitter tube temperature. The Corner Reflector Package Kit (part # 4334200) can be used only when the long axis of the heater is level and mounted in a horizontal position. PTS Series Only.

U-Bend Reflector Package Kit

Used with PTU series to maximize emitter tube temperatures and to reduce the clearences above thereflector. U-Bend Reflector Package Kit (Part #43488000) comes with the required couplings and hardware. PTU Series Only.

Tube Heater Accessories

Accessories for common tube heater installations include vent caps, combustion air termination caps, thermostats, programmable digital thermostats, 24V Thermostats relay kits, Thermostat enclosure, Chain Kits, Second Stage Line Regulators, and manual cutoff valves. To learn more click Tube Heater Accessories (PDF).

Troubleshooting

Troubleshooting Flowcharts are located toward the end of each products I & O pdf.

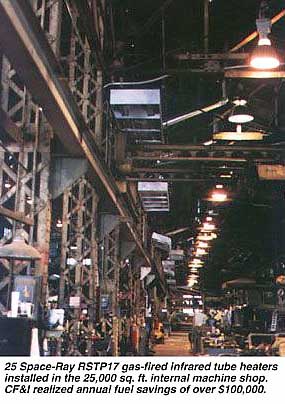

It has two 150-ton electric furnaces and two continuous casters. There are also rail, bar, rod, wire, seamless tube and other mills, a casting foundry and various auxiliary operations.

It has two 150-ton electric furnaces and two continuous casters. There are also rail, bar, rod, wire, seamless tube and other mills, a casting foundry and various auxiliary operations.

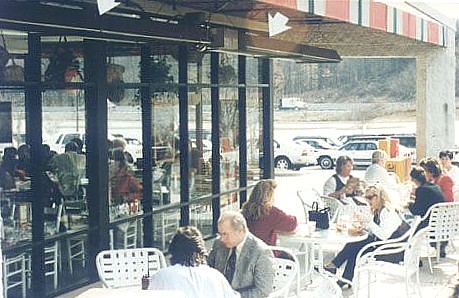

Now when it's cool outside and the heaters are on, often times we fill up the patio before the inside area which seats 75," he said. "Customers are amazed at how warm they are under the heaters when it's 30° Fahrenheit outside

Now when it's cool outside and the heaters are on, often times we fill up the patio before the inside area which seats 75," he said. "Customers are amazed at how warm they are under the heaters when it's 30° Fahrenheit outside