| SRB40CR | BTU/HR Input | Brooder Spacing | Min Mounting Height |

Ventilation Required* |

Gas Consumption |

| L2, L3, L5, L9 | 40,000 | 25-40′ | 62-72″ | 200 CFM | LP .43 GPH |

| N2, N5, N9 | 40,000 | 25-40′ | 62-72″ | 200 CFM | NG .40 THERM |

*Per Brooder

Control No. 2

Control No. 2

Control No. 3 and No. 9

Control No. 3 and No. 9

SRB40CR PILOT IGNITION CONTROL OPTIONS

CONTROL NO. 2

For single or multi-zone installations using central or multiple thermostats. This 24 volt AC zone type control can also operate using a 12 volt DC inverter as a backup. The gas valve includes a built-in regulator. A 24 volt power supply is required. Zone control panel (Part no. 4361905) and/or 24 volt thermostat, computer or environmental controller is required. 100% gas safety shut-off valve.

CONTROL NO. 3

BA modulating type HI/LO control with integral thermostat. No electrical supply is needed. Upon call for heat, valve will open from pilot to low fire (32,000 BTU/Hr.) and modulate between low and high fire as necessary to maintain desired temperature setting. When thermostat has been satisfied, valve will modulate down to low fire and then drop to pilot. 100% gas safety shut-off valve. Available only for use with propane gas.

CONTROL NO. 9

An individual, non-electric, fully automatic On/Off control with integral thermostat which operates on millivolts generated by the pilot – no electrical supply needed. Integral thermostat features a wide temperature range for easy adjustment. 100% gas safety shut-off valve.

| Control Suffix | Gas Type | Control Option Description | |||

| N2/L2 | Natural/Propane | For single or multi-zone installations using central or multiple thermostats. This 24 volt AC zone type control can also operate using a 12 volt DC inverter as a backup. The gas valve includes a built-in regulator. A 24 volt power supply is required. Zone control panel (Part No. 43619050) and/or 24 volt thermostat, computer or environmental controller is required. 100% gas safety shut-off valve. | |||

| L3 | Propane | A modulating type HI/LO control with integral thermostat. No electrical supply is needed. Upon call for heat, valve will open from pilot to low fire (25,000 BTU/Hr.) and modulate between low and high fire as necessary to maintain desired temperature setting. When thermostat has been satisfied, valve will modulate down to low fire and the drop to pilot. 100% gas safety shut-off valve. | |||

| N5/L5 | Natural/Propane | A 3-try direct spark ignition control for single or multi-zone installations. Gas valve includes a built-in regulator. A 24 volt power supply is required. Zone control panel (Part No. 43619050) and/or 24 volt thermostat, computer or environmental controller is required. For individual control, a unique thermostat (Part No. 43317050) is available. | |||

| N9/L9 | Natural/Propane | An individual, non electric, fully automatic On/Off control with integral thermostat which operates on millivolts generated by the pilot – no electrical supply needed. Integral thermostat features a wide temperature range for easy adjustment. 100% gas safety shut-off valve. | |||

- Low profile mounting bracket permits easy leveling of brooder

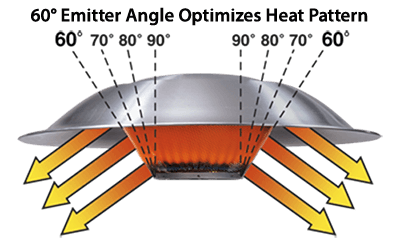

- Large deep dish canopy to efficiently reflect heat to litter area where it is needed most

- The stainless emitter assembly is fully insulated and enclosed. It features a full 3-year limited warranty

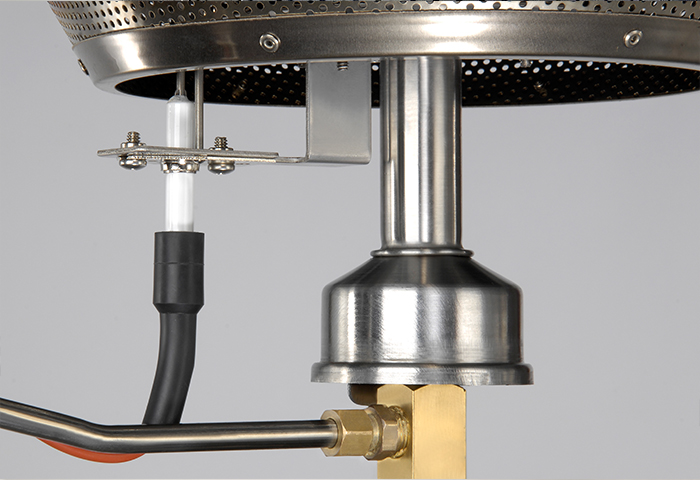

- The burner assembly with durable cast iron cap features large burner ports for more even heat distribution and years of trouble free service

- The safety pan helps to shield litter area directly beneath the brooder

- Has a stainless steel main burner gas line for strength and durability

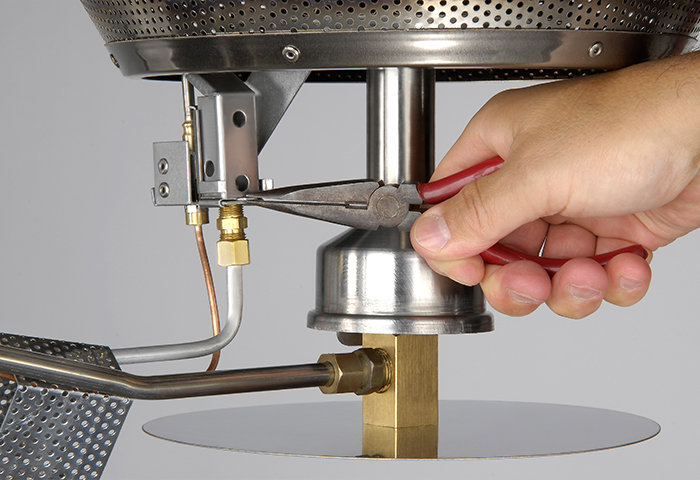

- The pilot models have easily removable shields for quick access to the pilot orifice

- The direct spark ignition model’s 3-try direct spark ignition is in a moisture resistant enclosure for added reliability

Patented WindBuster™ Pilot

The WindBuster Pilot System not onlyenhancesflame stability put provides dependable ignition for virtualtrouble-free operation, even with speeds up to 7 mph (11.2 km)

Maintenance Friendly

| Model | Control Type | BTU/HR Input | Canopy Diameter | Brooder Height | Shipping Weight |

| SRB40CR | Pilot | 40,000 | 35″ | 18″ | 23 lbs. |

| SRB40CR | Direct Spark | 40,000 | 35″ | 18″ | 28 lbs. |

| Gas Type | Control Type | Burner Pressure | Supply Pressure Min |

Supply Pressure Max |

Voltage | Amps |

| Natural | #2Pilot | 4″wc | 5″wc | 14″wc | 24VAC | 0.5 |

| Natural | #9Pilot | 4″wc | 4.5″wc | 5.5″wc | N/A | N/A |

| Propane | #2Pilot | 10″wc | 11″wc | 14″wc | 24VAC | 0.5 |

| Propane | #3Pilot | 10″wc | 11″wc | 14″wc | N/A | N/A |

| Propane | #9Pilot | 10″wc | 11″wc | 14″wc | N/A | N/A |

| Natural | #5Direct Spark | 4″wc | 5″wc | 14″wc | 24VAC | 0.8 |

| Propane | #5 Direct Spark | 10″wc | 11″wc | 14″wc | 24 VAC | 0.8 |

| Model | Sides | Ceiling | Below |

| SRB40CR | 36″ | 18″ | 48″ |

Zone Control Panel Model ZCP22, Part #43619050

This is power supply control which utilizes a 375VA transformer to provide the required 24VAC for single or multiple groups (zones) of No. 2 or No. 5 brooders.

Use power inverter kit #43619070 for batter back-up.

Power Inverter Kit (for battery back-up), Part #43619070

This provides temporary 120VAC to the brooder zone control (power supply) panel during power outages.The kit includes a batter trickle charger, changeover relay and power inverter to convert 12 volt DC into 120 volt AC.

Need Image

Transformer Replacement – 375VA 120/240VAC – 24VAC Part #30222070

Need copy

Thermostat – Environmental (EW-4-20), Part #30525010

Ratings: SPDT 120/240VAC, 16A full load

Temperature range: -40° F to 104° F +/- 2.5° F differential

Housing: Watertight ABS plastic meets NEMA 4x and NEC Article 547-4 requirements for use in harsh environments.

Adjustable dial allows thermostat to be recalibrated.

Thermostat – Individual, Part #43317060 (for No. 5 Control only)

Temperature range: 58° F to 122° F with (10) temperature scale ranges. The thermostat is used to control individual brooders for Turkey heating applications. Includes Mears thermostat, plastic enclosure, bracket and screws to mount to White Rodgers 25M gas valve.

Hose Kits

Hose Kits – No. 2 & No. 5 Controls:

Part #30522061

6’ Hose with 3/8” swivel female flare fittings and 6” spring.

Part #30522101

10’ Hose with 3/8” swivel female flare fittings and 6” spring.

Each kit includes (2) 45° flare fittings (3/8” tube x ½” NPT) for connection to main gas valve and manual shut off valve.

Hose Kits – No. 3 & No. 9 Controls:

Part #30522060

6’ Hose with 3/8” swivel female flare fittings and 6” spring.

Part #30522100

10’ Hose with 3/8” swivel female flare fittings and 6” spring.

Each kit includes (1) 45° flare fitting (3/8” tube x ½” NPT) for connection to manual shut-off valve and (1) 45° flare fitting (3/8” tube x 3/8” NPT) for connection to main gas valve.

Manual Gas Shut-Off Ball Valve – ½” NPT, Part #30285000

The Deflector Kit (Part # 43504000) is used to reduce clearances to combustibles below the heater. It is designed to be used when the CB series is installed in a horizontal position.

Wire Brushes

Wire Brush – Long, Part #43295020

Wire Brush – Short, Part #43295010

Troubleshooting

Troubleshooting Flowcharts are located toward the end of each products I & O pdf.