| LoPro | BTU/HR Input | Brooder Spacing | Min Mounting Height |

Ventilation Required* |

Gas Consumption |

| LPBL42-N5/L5 | 42,000 | 25-40′ | 72″ | 200 CFM | .46 GPH.42 THERM |

| LPBH40-N5/L5 | 40,000 | 25-40′ | 72″ | 200 CFM | .43 GPH.40 THERM |

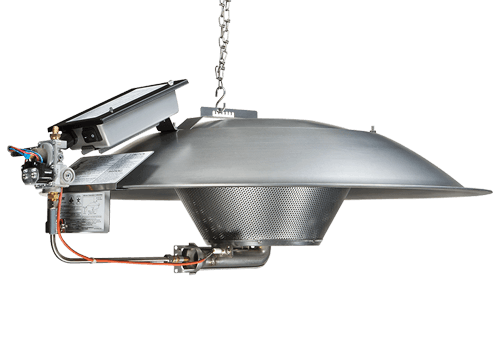

- Up To A Powerful 42,000 BTU/Hr.

- 5% More Heat Than Other Brooders.

- Low Pressure & High Pressure Models Available.

- 13” tall vs the 18” tall profile of our standard SRB and Tru40 models

- Factory Pre-Assembled Components For Quick Install.

- Corrosion Resistant Materials To Resist Humidity And

Ammonia. - Dual Fuel Regulator Convert Between Gas Types With

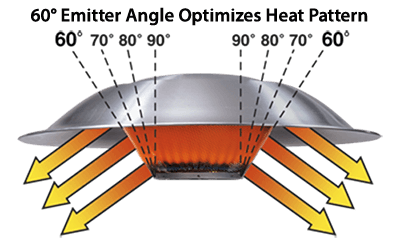

Just An Orifice Change. - Unique 60° Emitter Angle.

- Puts More Radiant Heat Into The Primary Brood Area.

- 3-Year Limited Warranty.

- Direct Spark Ignition.

- Water Resistant Ignition Control Box.

- All Stainless Steel & Aluminum Construction.

- 24V Or 120V Power Supply Available.

- Zone Control Panel Available.

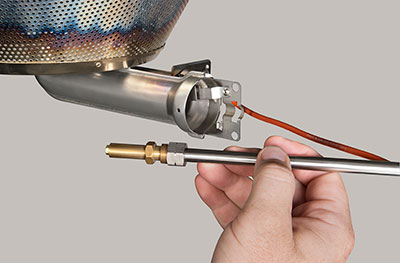

Maintenance Friendly

| Model | Control Type | BTU/HR Input | Canopy Diameter | Brooder Height | Shipping Weight |

|

LPBL42-N5/L5 |

Direct Spark | 42,000 | 35″ | 13″ | 19 lbs. |

|

LPBH40-N5/L5 |

Direct Spark | 40,000 | 35″ | 13″ | 19 lbs. |

| Pressure | Gas Type | Control Type | Burner Pressure | Supply Pressure Min |

Supply Pressure Max |

Voltage | Amps |

| Low Pressure | Natural | #5 Direct Spark | 4″wc | 5″wc | 14″wc | 24 VAC | 0.8 |

| Low Pressure | Propane | #5 Direct Spark | 10″wc | 11″wc | 14″wc | 24 VAC | 0.8 |

| High Pressure | Natural | #5 Direct Spark | 5.0 PSIG (345 mbar) |

5.0 PSIG (345 mbar) |

5.0 PSIG (345 mbar) |

120 VAC | 0.5 |

| High Pressure | Propane | #5 Direct Spark | 5.0 PSIG (345 mbar) |

5.0 PSIG (345 mbar) |

5.0 PSIG (345 mbar) |

120 VAC | 0.5 |

| Model | Sides | Ceiling | Below |

| LoPro | 36″ | 18″ | 72″ |

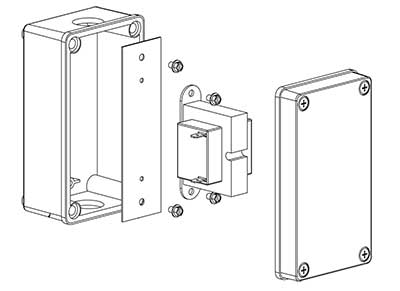

Zone Control Panel Model ZCP22, Part #43619050

This is power supply control which utilizes a 375VA transformer to provide the required 24VAC for single or multiple groups (zones) of No. 2 or No. 5 brooders.

Use power inverter kit #43619070 for batter back-up.

120V accessory for the LPBL – p/n 44195160

Power Inverter Kit (for battery back-up), Part #43619070

This provides temporary 120VAC to the brooder zone control (power supply) panel during power outages.The kit includes a batter trickle charger, changeover relay and power inverter to convert 12 volt DC into 120 volt AC.

Transformer Replacement – 375VA 120/240VAC – 24VAC Part #30222070

Thermostat – Environmental (EW-4-20), Part #30525010

Ratings: SPDT 120/240VAC, 16A full load

Temperature range: -40° F to 104° F +/- 2.5° F differential

Housing: Watertight ABS plastic meets NEMA 4x and NEC Article 547-4 requirements for use in harsh environments.

Adjustable dial allows thermostat to be recalibrated.

Thermostat – Individual, Part #43317050 (for No. 5 Control only)

Temperature range: 58° F to 122° F with (10) temperature scale ranges. The thermostat is used to control individual brooders for Turnkey heating applications. Includes Mears thermostat, plastic enclosure, bracket and screws to mount to Honeywell #VR8205 gas valve.

Hose Kits

Hose Kits – No. 2 & No. 5 Controls:

Part #30522061

6’ Hose with 3/8” swivel female flare fittings and 6” spring.

Part #30522101

10’ Hose with 3/8” swivel female flare fittings and 6” spring.

Each kit includes (2) 45° flare fittings (3/8” tube x ½” NPT) for connection to main gas valve and manual shut off valve.

Hose Kits – No. 3 & No. 9 Controls:

Part #30522060

6’ Hose with 3/8” swivel female flare fittings and 6” spring.

Part #30522100

10’ Hose with 3/8” swivel female flare fittings and 6” spring.

Each kit includes (1) 45° flare fitting (3/8” tube x ½” NPT) for connection to manual shut-off valve and (1) 45° flare fitting (3/8” tube x 3/8” NPT) for connection to main gas valve.

Manual Gas Shut-Off Ball Valve – ½” NPT, Part #30285000

The Deflector Kit (Part # 43504000) is used to reduce clearances to combustibles below the heater. It is designed to be used when the CB series is installed in a horizontal position.

Wire Brushes

Wire Brush – Long, Part #43295020

Wire Brush – Short, Part #43295010

Troubleshooting

Troubleshooting Flowcharts are located toward the end of each products I & O pdf.