| Model | Single StageBTU/HR Input | Two Stage BTU/HRHigh Input | Two Stage BTU/HR Low Input | Min Mounting Height |

| PCA/SS75 | 75,000 | 75,000 | 50,000 | 8′ |

| PCA/SS100 | 100,000 | 100,000 | 65,000 | 8′ |

| PCA/SS125 | 125,000 | 125,000 | 80,000 | 9′ |

| PCA/SS150 | 150,000 | 150,000 | 100,000 | 9′ |

| Control Suffix | Gas Type | Control Option Description | ||

| N5/L5 | Natural/Propane | Single Stage Gas Valve – Single Stage Input | ||

| N7/L7 | Natural/Propane | Two Stage Gas Valve – Modulating Input -High/Low Fire | ||

| Model | Single Stage BTU/HR Input |

Two Stage BTU/HR High Input |

Two Stage BTU/HR Low Input |

Total Tube Length |

Overall Dimension |

Shipping Weight |

| PCA/SS75 | 75,000 | 75,000 | 50,000 | 20′ | 21 ‘2″ | 122 lbs |

| PCA/SS75 | 75,000 | 75,000 | 50,000 | 30′ | 31′ 2″ | 157 lbs |

| PCA/SS100 | 100,000 | 100,000 | 65,000 | 30′ | 31′ 2″ | 157 lbs |

| PCA/SS100 | 100,000 | 100,000 | 65,000 | 40′ | 41′ 2″ | 192 lbs |

| PCA/SS125 | 125,000 | 125,000 | 80,000 | 40′ | 41′ 2″ | 192 lbs |

| PCA/SS125 | 125,000 | 125,000 | 80,000 | 50′ | 51′ 2″ | 232 lbs |

| PCA/SS150 | 150,000 | 150,000 | 100,000 | 50′ | 51′ 2″ | 232 lbs |

| PCA/SS150 | 150,000 | 150,000 | 100,000 | 60′ | 61′ 2″ | 274 lbs |

| Gas Type | Control Type | Single Stage Burner Pressure | Two Stage Burner Pressure High | Two Stage Burner Pressure Low | Supply Pressure Min | Supply Pressure Max | Voltage * | Amps |

| Natural | N5 | 3.5″wc | 5″wc | 14″wc | 120VAC | 1.74 | ||

| Natural | N7 | 3.5″wc | 1.4″wc | 5″wc | 14″wc | 120VAC | 1.8 | |

| Propane | L5 | 10″wc | 11’wc | 14″wc | 120VAC | 1.74 | ||

| Propane | L7 | 10″ wc | 4.0″ wc | 11’wc | 14″wc | 120 VAC | 1.8 |

| Gas Type | Model | 0° Angle Sides | 0° Angle Ceiling* | 0° Angle Below | 0° Angle Ends | 45° Angle Front | 45° Angle Rear |

| PCA/SS75 | 27″ | 6″ | 60″ | 30″ | 48″ | 12″ | NA |

| PCA/SS100 | 66″ | 6″ | 88″** | 40″ | 66″ | 20″ | NA |

| PCA/SS125 | 66″ | 6″ | 101″** | 40″ | 66″ | 20″ | NA |

| PCA/SS150 | 84″ | 6″ | 106″** | 48″ | 84″ | 24″ | NA |

*When used indirect vented, minimum clearance for CEILING must be: 12″ for PCS/PCA 75 and 18″ for PCS/PCA 100-150. If optional corner and u-bend reflectors are not used, the clearance must be 18″.

** Maximum clearance below reduces to 72″ once you are 20′ downstream from the burner box.

End Reflector Package, Part #43341000

(1 pkg. per straight configuration series or 2 pkgs. per U configuration series with the optional U-bend)

Contains:

End Reflector, #43320000….Qty-2

Speed Clips, #02266010….Qty-8

Two Stage Relay Package, Part #44195000

(One per heater required) for controlling multiple heaters with a single 24V thermostat

Contains:

Relay Board, #30740000….Qty-1

ABS Enclosure, #30709059….Qty-1

Mounting Plate, #30709058….Qty-1

Water Tight Connectors, #30635010….Qty-2

#6-32×5/8” Screws, #02242030….Qty-2

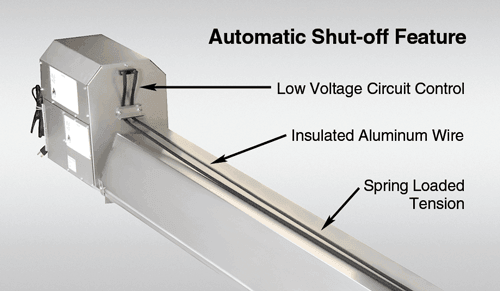

Cold air Stopper, Part #30683000

Improves heating efficiency by preventing cold air during winter (warm air during summer) from entering your poultry house when the heating system is off.

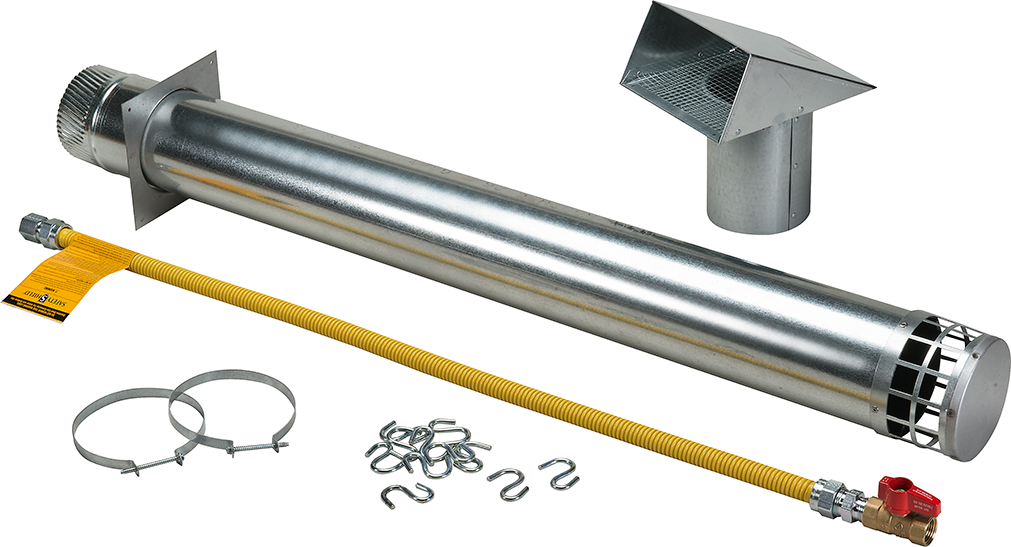

Poultry Tube Heater Accessories

These accessories are included with every Space-Ray tube heater as standard equipment. Pictured above are S hooks, exhaust hood, flexible gas connector, manual shut-off valve and fresh air intake. Also included but not shown the wire hangars and end reflectors.