| Model | BTU/Hr Input | Min. Mounting Height | Max. Mounting Height | Ventilation Required | Gas Consumption |

| SHP 2 | 4,200 BTU/Hr | 20″ | 30″ | 18 CFM | 0.046 GPH |

| SHP 3 | 7,000 BTU/Hr | 24″ | 40″ | 28 CFM | 0.076 GPH |

| SHP 8 | 17,100 BTU/Hr | 48″ | 60″ | 68 CFM | 0.19 GPH |

| SHP 17B | 17,000 | 48″ | 60″ | 60 CFM | 0.19 GPH |

| Model | Control Suffix | Gas Type | Control Option Description |

| SHP 2 | L6 | Propane | A manual valve with flame failure safety protection that is unregulated for use with an individual thermostat or a modulating or thermostatic control panel. |

| SHP 3 | L6 | Propane | |

| SHP 8 | L6 | Propane | A manual valve with flame failure safety protection that is unregulated for use with an individual thermostat or a modulating or thermostatic control panel. |

| SHP 17B | L6 | Propane | A manual valve with flame failure safety protection that is unregulated for use with a separate external gas control (e.g. modulating or thermostatic control panel). |

| Model | Coverage | |

| SHP 8 | Pigs | Up To 170 |

| SHP 8 | Broilers | Up To 1,500 |

| SHP 8 | Turkeys | Up To 500 |

| SHP 17B | Pigs | Up To 170 |

| SHP 17B | Broilers | Up To 1,500 |

| SHP 17B | Turkeys | Up To 500 |

| Model | BTU/Hr Input | Canopy Diameter | Brooder Height | Net Weight |

| SHP 2 | 4,200 BTU/Hr | 8.5″ | 7″ | 2.2 lbs. |

| SHP 3 | 7,000 BTU/Hr | 8.5″ | 7″ | 2.2 lbs. |

| SHP 8 | 1,700 BTU/Hr | 13.5″ | 7″ | 3.3 lbs. |

| SHP 17B | 17,000 | 16.7″ | 9″ | 6 lbs. |

| Model | Gas Type | Control Type | Supply Pressure Min | Supply Pressure Max. | Voltage | Amps |

| SHP 2 | Propane | #6 | 10″ wc | 4.5 psi | N/A | N/A |

| SHP 3 | Propane | #6 | 10″ wc | 4.5 psi | N/A | N/A |

| SHP 8 | Propane | #6 | 10″ wc | 4.5 psi | N/A | N/A |

| SHP 17B | Propane | #6 | 10″ wc | 5 psi | N/A | N/A |

| Model | Sides | Ceiling | Below |

| SHP 2 | 20″ | 20″ | 20″ |

| SHP 3 | 20″ | 20″ | 20″ |

| SHP 8 | 30″ | 30″ | 30″ |

| SHP 17B | 36″ | 17″ | 42″ |

Note: All SHP 2’s & SHP 3’s include an Air Filter as Standard Equipment.

All SHP8’s include an Air Filter as Standard Equipment.

New installations require 17M Gas Hose Kit, Part No. 30522250.(Hose Kit includes a 6′ X 1/4” gas hose, quick connect fitting and an on/off gas valve.)

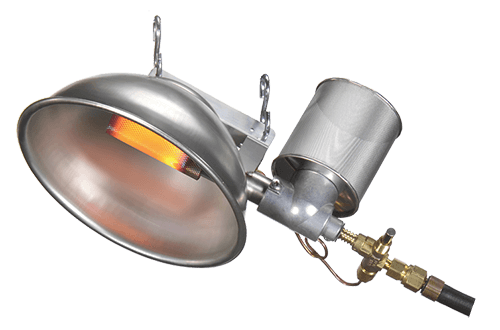

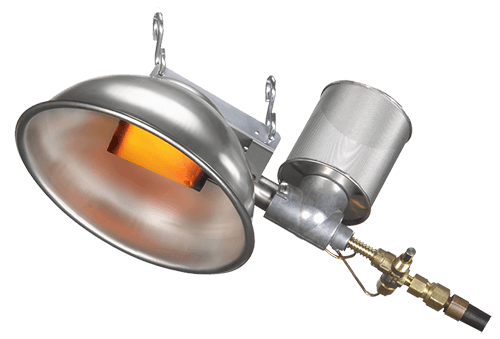

SHP17B Air Filter

In reasonably clean operating environments, an air filter is unnecessary because of the SHP17B’s unique double gas burner system that combusts dust and carbon to help prevent buildup. Space-Ray offers the air filter option shown here for use in harsh agricultural environments.

Space-Ray SHP Series Thermostat & Control Panel Options

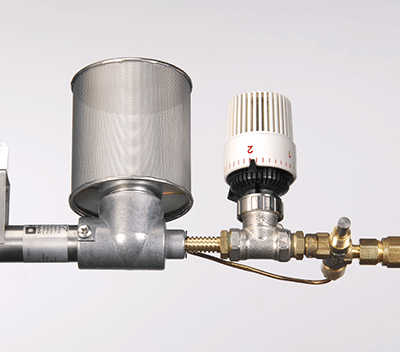

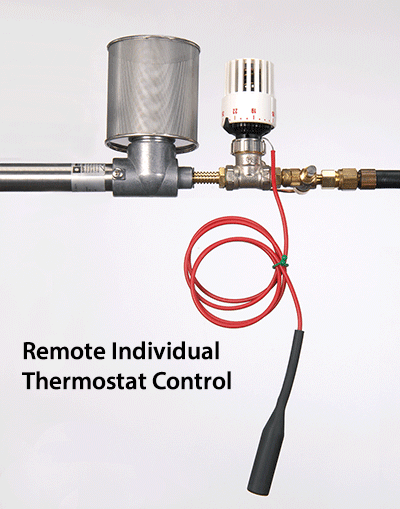

Thermostat Options

Space-Ray’s SHP Series is available with two thermostat options. The Individual Thermostat Control provides easy and convenient ambient temperature control. The Remote Individual Thermostat Control (shown at far right) features a remote sensor that can be lowered to floor level for more precise reading of the temperature at liter level.

Modulating Controllers

Space-Ray’s SHP Series, when combined with either one of Space-Ray’s economical High/Low control panels, can provide one of the highest fuel efficiencies of any brooder on the market today – dramatically increasing profits by reducing your cost of operation by up to 20%.

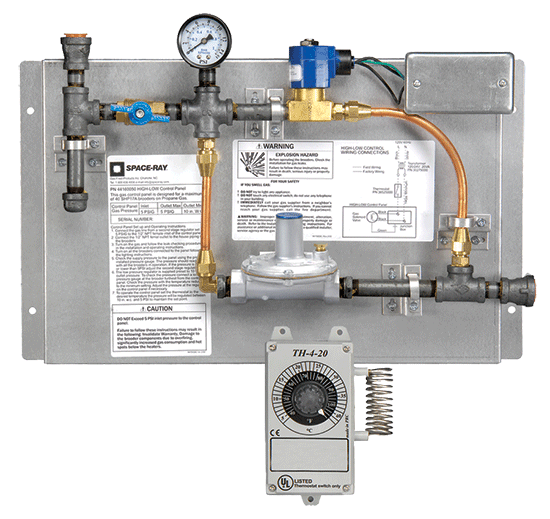

Non-Electric Modulating Controller, Part #44160000

The SHP17 modulating control panel requires no electricity for operation. It automatically controls the output level of the brooder based on the thermostat’s requirements.

Hi/Lo Modulating Controller with EW-4-20 Thermostat, Part #44160050

Space-Ray’s unique High/Low control panels provide up to 20% lower fuel consumption by automatically adjusting the brooder’s output from maximum heat output to the minimum heat output in just second

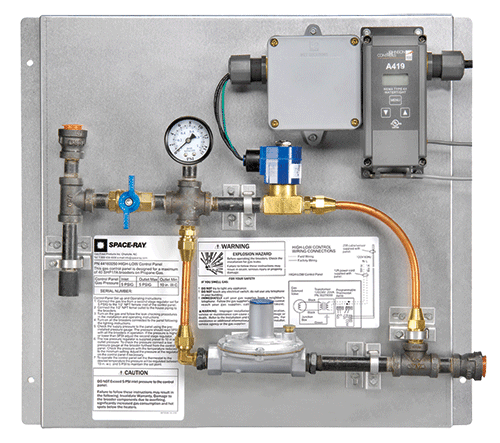

Hi/Lo Modulating Controller with A419 Digital Electronic Thermostat, Part #44160100

Space-Ray’s unique High/Low control panels provide up to 20% lower fuel consumption by automatically adjusting the brooder’s output from maximum heat output to the minimum heat output in just seconds.

Hose Kit – New Installation, Part #30522250

The hose kit is available for new installations using a ½” gas line that includes a ½” manual ball valve, ½” x ¼”bushing, ¼” close pipe nipple, quick disconnect socket, ¼” ID x 6’ hose with quick disconnect fitting, and an adaptor fitting to connect to the hose.

Hose Kit – Existing Installation, Part #30522260

The hose kit is for existing installations which includes the hose and adaptor fitting to connect the brooder. The hose has a quick disconnect fitting to connect to a Sturgis #104051 female quick disconnect fitting.

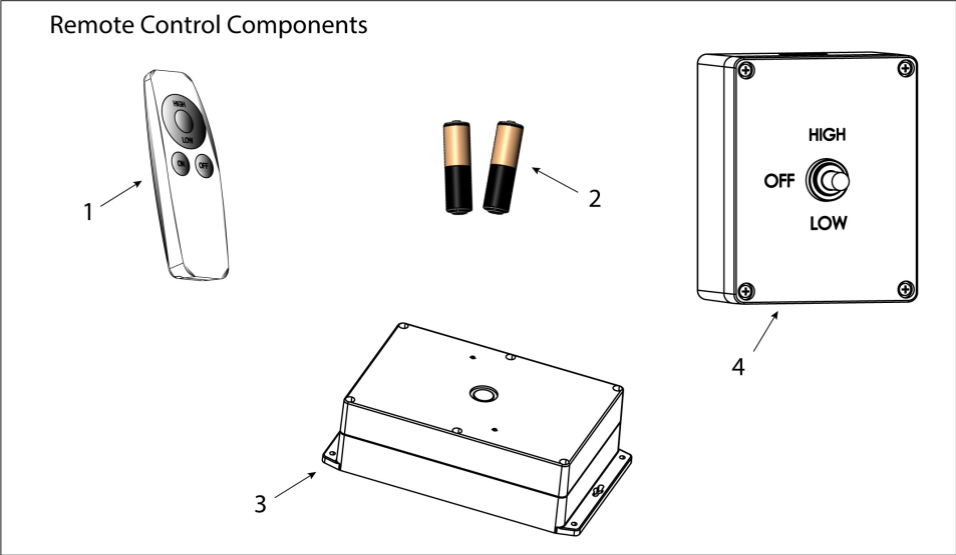

Remote Control Kit, Part #44640080

Air Filter, Part #30744000 (x 2 each)

Under normal operating conditions, an air filter is unnecessary because of the brooder’s unique double gas burner system that combusts dust and carbon to help prevent Buildup. Space-Ray offers the air filter option shown here For use in harsh agricultural environments.

Troubleshooting

Troubleshooting Flowcharts are located toward the end of each products I & O pdf.