Space-Ray Heating has been providing farmers with reliable and energy efficient heating solutions that they can trust since 1949.

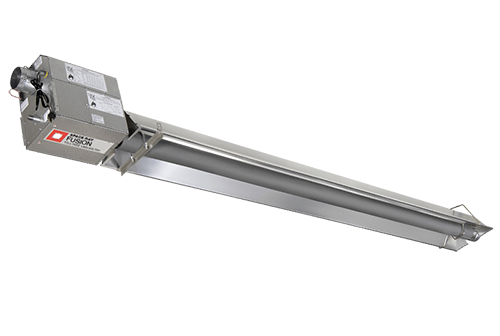

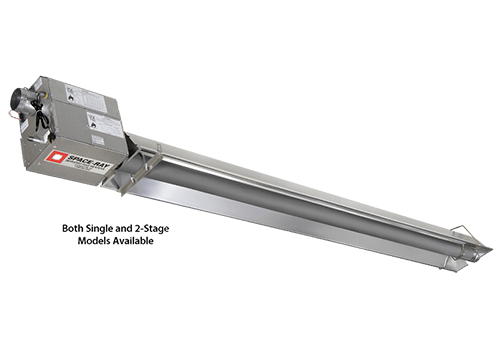

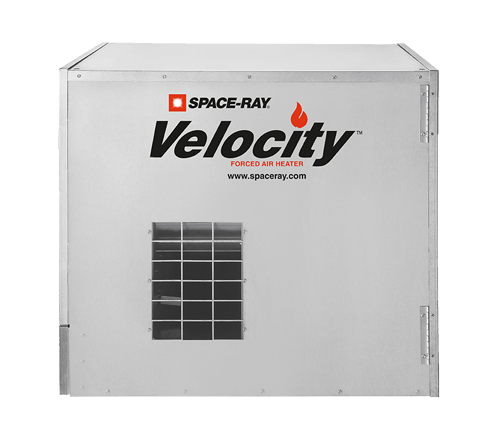

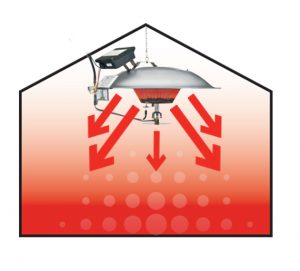

Space-Ray is the leading industry manufacturer and provides a complete line of heating systems for a variety of poultry, swine and other animal applications. Our heaters are designed to increase cost savings, are energy efficient and overall, lower the costs of everyday poultry and hog production.

Our heaters and brooders are specifically designed for broiler chicken houses, pig buildings and pig complexes, and all other poultry and swine applications.