<tdvalign=”MIDDLE” sdnum=”1033;1033;General”>DK30

| MODEL | GAS TYPE | INPUT BTU/HR | NO. OF BURNERS | MINIMUM MOUNTING HEIGHT (feet) |

| Natural | 30,000 | 1 | 11 | |

| DK35 | Natural | 35,000 | 1 | 12 |

| DK40 | Natural | 40,000 | 1 | 12 |

| DK60 | Natural | 60,000 | 2 | 13 |

| DK70 | Natural | 70,000 | 2 | 13 |

| DK80 | Natural | 80,000 | 2 | 14 |

| DK100 | Natural | 100,000 | 3 | 15 |

| DK120 | Natural | 120,000 | 3 | 16 |

| DK140 | Natural | 140,000 | 4 | 17 |

| DK160 | Natural | 160,000 | 4 | 18 |

| DK33 | Propane | 33,000 | 1 | 12 |

| DK66 | Propane | 66,000 | 2 | 13 |

| DK100 | Propane | 99,000 | 3 | 15 |

| DK132 | Propane | 132,000 | 4 | 17 |

Floor Level Coverage – The above chart may be used as a guideline for primary radiation, i.e. the infrared pattern directly below the heater. In a well-insulated building, only 50% of the floor needs to be covered by the primary radiant pattern. Please be aware that the radiant energy generated by infrared heaters is not limited to the primary radiant pattern. There is additional radiant energy that is absorbed outside the primary area, a secondary radiant pattern. Since concrete is a very good conductor of heat, a reasonably uniform floor temperature eventually will be reached. The amount of time it takes to reach “thermal equilibrium” is in direct correlation to the distance between the heaters.

Learn More >>

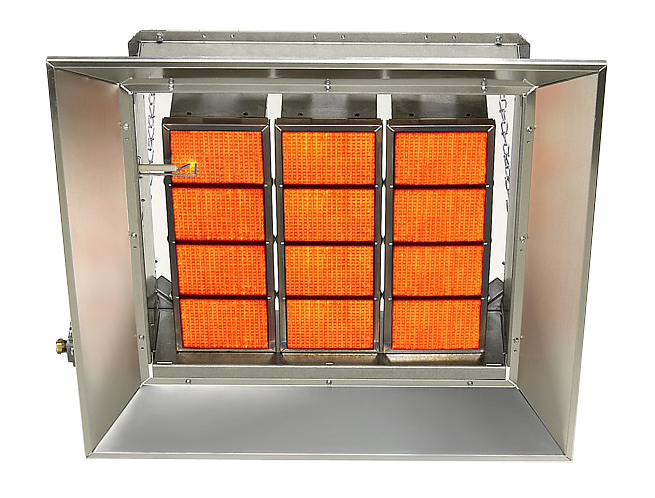

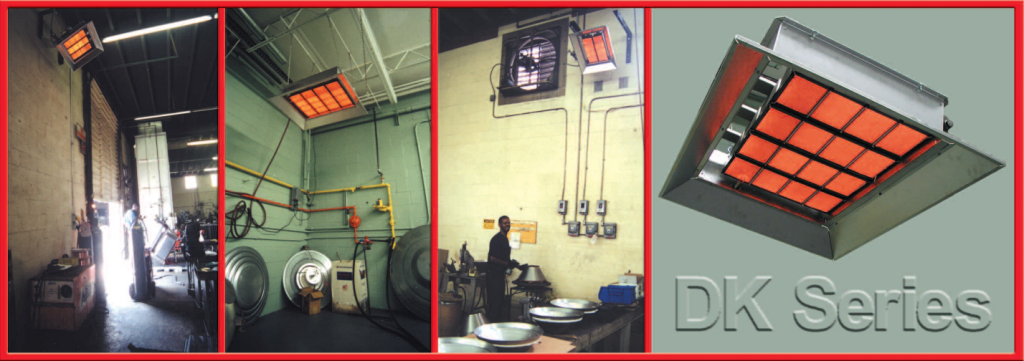

BURNER AND BODY CONSTRUCTION

- Modular burner construction and venturi

- Heavy gauge aluminized steel burner head and venturi

- Stainless Steel tile retainer assembly

- Corrosion resistant aluminized steel body construction

EMITTER SURFACE

- Special honeycomb tile design for increased radiant output

- Up to 1800° surface temperature

- 5-Year Limited Warranty on emitter tiles

- Optional incoloy 800 reverberatory screen for secondary radiating surface and additional safety

REFLECTOR

- Highly efficient aluminum reflectors

- Double-formed edges for rigidity

- Optional parabolic extension for higher mounting heights

OTHER

- Simple chain mounting

- ½” NPT female gas pipe connection

- 120 volt electrical supply (0.4 Amp draw)

- 120/24 volt transformer included

- Heaters can be shipped by UPS

- CSA Certified according to ANSI Z83.19 and CSA 2.34. NOT Certified for Residential Use

| MODEL | GAS TYPE | INPUT BTU/HR | NO. OF BURNERS | DIMENSIONS (inches) | SHIPPING WEIGHT (lbs.) | ||

| LENGTH | WIDTH | HEIGHT | |||||

| DK30 | Natural | 30,000 | 1 | 25.75 | 15.75 | 8.25 | 34 |

| DK35 | Natural | 35,000 | 1 | 25.75 | 15.75 | 8.25 | 34 |

| DK40 | Natural | 40,000 | 1 | 25.75 | 15.75 | 8.25 | 34 |

| DK60 | Natural | 60,000 | 2 | 25.75 | 21.75 | 8.25 | 41 |

| DK70 | Natural | 70,000 | 2 | 25.75 | 21.75 | 8.25 | 41 |

| DK80 | Natural | 80,000 | 2 | 25.75 | 21.75 | 8.25 | 41 |

| DK100 | Natural | 100,000 | 3 | 25.75 | 25.75 | 8.25 | 52 |

| DK120 | Natural | 120,000 | 3 | 25.75 | 25.75 | 8.25 | 52 |

| DK140 | Natural | 140,000 | 4 | 25.75 | 34 | 8.25 | 59 |

| DK160 | Natural | 160,000 | 4 | 25.75 | 34 | 8.25 | 59 |

| DK33 | Propane | 33,000 | 1 | 25.75 | 15.75 | 8.25 | 34 |

| DK66 | Propane | 66,000 | 2 | 25.75 | 21.75 | 8.25 | 41 |

| DK100 | Propane | 99,000 | 3 | 25.75 | 25.75 | 8.25 | 52 |

| DK132 | Propane | 132,000 | 4 | 25.75 | 34 | 8.25 | 59 |

| GAS TYPE | BURNER PRESSURE | MINIMUM SUPPLY PRESSURE | MAXIMUM SUPPLY PRESSURE | VOLTAGE | AMPS | IGNITION TYPE |

| NATURAL | 6″ W.C. | 7″ W.C. | 14″ W.C. | 120 VAC 60HZ | 0.4 | DIRECT SPARK |

| PROPANE | 10″ W.C. | 11″ W.C. | 14″ W.C. |

| Model No. | Sides | Ceiling | Below | Below (35°) | Front (35°) | Rear (35°) | Angle Mtg. (degree) | ||

| Standard Reflector | w/Parabolic Extension | Standard Reflector | w/Parabolic Extension | ||||||

| DK30 DK35 DK33 DK40 |

30″ | 36″ | 72″ | 72″ | 100″ | 36″ | 50″ | 30″ | 0 min 35 max |

| DK60 DK70 DK66 DK80 |

48″ | 48″ | 98″ | 98″ | 137″ | 48″ | 68″ | 36″ | 0 min 35 max |

| DK100 DK120 |

48″ | 64″ | 128″ | 128″ | 180″ | 60″ | 84″ | 48″ | 0 min 35 max |

| DK132 DK160 DK140 |

60″ | 64″ | 136″ | 136″ | 190″ | 64″ | 90″ | 48″ | 10 min 35 max |

NOTE:The clearances specified above must be maintained to combustibles and other materials that may be damaged by temperatures 90°F above ambient temperature. Clearances to combustibles are posted on the reflector near the control end of the heater. In locations used for storage of combustible materials where they may be stacked below the heater, NFPA 54 requires that the installer must post signs that will “specify the maximum permissible stacking height to maintain the required clearances from the heater to combustibles”.

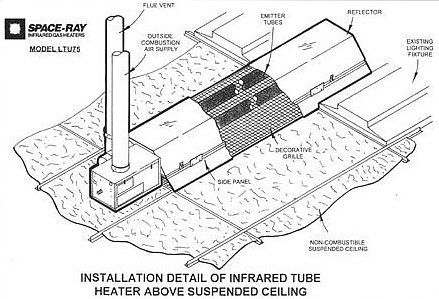

VENTING REQUIREMENTS

Heaters can be common vented, vented or indirect vented. A vented installation must be vented outside the building with a flue pipe. An indirect vented installation requires a minimum ventilation flow of 4 CFM per 1000 BTU/hour of total installed heater capacity on natural gas by either gravity or power ventilation (4.18 CFM per 1000 BTU/hour on propane).

INSTALLATION REQUIREMENTS

Installation and service must be performed by a licensed contractor. The installation must conform to written Instalation & Operating Instructions and local codes. In the absence of local codes, the installation must conform with the National Fuel Gas code, ANSI Z223.1 (latest edition also known as NFPA54) or GCA B149 (latest edition) installation codes. These codes are available from the National Fire Protection Association, Inc., Batterymarch Park, Quincy, MA 02269 or the Canadian Gas Association, 55 Scarsdale Road, Toronto, Ontario M3B 2R3, CANADA.

FOR YOUR SAFETY

Operate infrared heaters with proper care and observe all safety precautions. Carefully follow printed installation, operating and cleaning instructions furnished with the heater. Do not store gasoline or combustible products in the vicinity of the heater. Do not touch the heater or the tubes while the heater is in operation. Adequate ventilation must always be provided in accordance with codes.

Parabolic Reflector Extension

The Parabolic Reflector Extension is used to increase the intensity of the heater by focusing inrared energy in a narrower area for spot heating applications. Details on Parabolic Reflector Extension Kit (PDF)

Troubleshooting

Troubleshooting Flowcharts are located toward the end of each products I & O pdf.

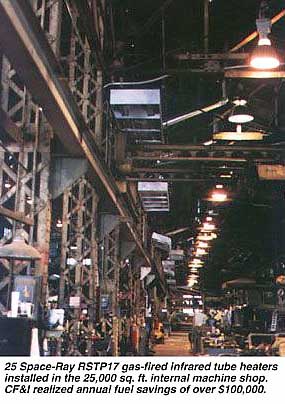

It has two 150-ton electric furnaces and two continuous casters. There are also rail, bar, rod, wire, seamless tube and other mills, a casting foundry and various auxiliary operations.

It has two 150-ton electric furnaces and two continuous casters. There are also rail, bar, rod, wire, seamless tube and other mills, a casting foundry and various auxiliary operations.

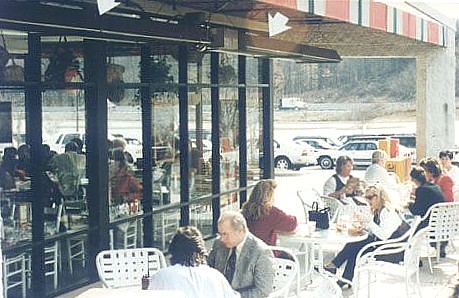

Now when it's cool outside and the heaters are on, often times we fill up the patio before the inside area which seats 75," he said. "Customers are amazed at how warm they are under the heaters when it's 30° Fahrenheit outside

Now when it's cool outside and the heaters are on, often times we fill up the patio before the inside area which seats 75," he said. "Customers are amazed at how warm they are under the heaters when it's 30° Fahrenheit outside