COMMERCIAL & INDUSTRIAL

Commercial & Industrial Case Studies

Case Study: RESTORATION OF BOSTON CASTLE

SPACE-RAY INSTRUMENTAL IN RESTORATION OF BOSTON CASTLE, A NATIONAL HISTORIC LANDMARK

BOSTON, MA - The management of The Castle at the Park Plaza Hotel retained McDonald & Associates of Boston to renovate the building which consists of a 100 foot wide and 200 foot long function and exhibition room for dances, weddings, receptions, exhibits, and special events accommodating groups up to 2000. Built in 1891 as an armory for the First Corps of Cadets, the building has been designated as a National Historic Landmark.

The renovation plan called for the removal of every possible element added after 1950 within the building.

One of the first places McDonald turned to was the 20,000 sq. ft. insulated drop ceiling. It had been installed over the large room in the 1970's to accommodate two 937,000 Btu/hr forced-air furnaces.

"Our objective was to highlight the ornate decorative detail throughout the space, and reveal important architectural and engineering accomplishments of the roof support structure," said McDonald & Associates co-owner Bruce McDonald.

Off came the ceiling and out popped the surprises.

"We had no idea what was up there," said McDonald. "What we found was an original vaulted ceiling that peaked 66 feet above the floor; a scissor-truss roof support system that, to me, was on par with the Eiffel Tower; three skylights; 200 Tivoli lights; a full-view balcony situated at either end of the room; six dormers; and a beautiful 8-1/2 foot diameter clock that was still in operation."

The first challenge involved finding an alternative heating system that would not obscure the splendor of the building and, at the same time, be aesthetically appealing and cost-efficient.

All parties opted for the placement of six pairs of LTU 175-40 low-intensity tube heaters at 36 ft. above the finished floor, on either side of the building and equally spaced for optimum efficiency. According to McDonald, the total heating system capacity is 2,100,000 Btuh, with the six zones thermostatically controlled.

"The difference the heaters made in the architecture, engineering, and aesthetics is tremendous," said McDonald. "We installed a system that doesn't make as much noise, that distributes heat evenly, and provides a more comfortable heating environment."

To compensate for the increased heat loss once the insulated drop ceiling was removed, McDonald said input capacity of the heating system was increased by 11%. According to Condon, a conventional heating system would have required an increase of 47.7%, or 892,500 Btuh of input capacity.

McDonald said it was the first application in a special-event space design using radiant heaters.

The radiant heaters are a major improvement over the old heating system, and are instrumental in increasing use of the facility and adding to the occupancy of the hall.

"We will attract a more upscale type of event," said Todd Saunders, vice president of The Saunders Hotel Group. "The facility also will be used at greater capacity more frequently. This is the trend we are already seeing."

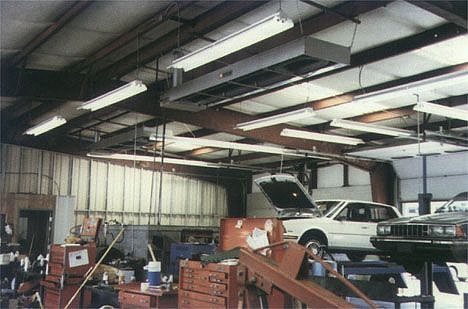

Case Study: AUTO DEALER SAVES 30% IN SERVICE AREA HEATING COSTS

When Joe Sheffield, owner of Sheffield Pontiac/ Buick/GMC auto dealership in Johnson City, TN, was seeking a heating system for his 6,000 sq. ft service and repair shop, he considered conventional forced-air gas unit heaters, gas infrared heaters and electric heaters.

Sheffield consulted the local gas company and visited several area auto dealerships, looking at their heating systems. As a result of his search, he decided to install three RSTP17-L5, 175,000 Btu/hr LP gas tube heaters from the Space-Ray Division of Gas-Fired Products Inc., Charlotte, NC.

"Several of my customers installed Space-Ray radiant heaters in the past and were pleased with the results," stated Sherrill Parker of Holstein Gases. "All were impressed with the fuel savings, high radiant efficiency and comfortable work environment that the units provided. For these reasons, it was easy for me to recommend a radiant heating system."

Proven fuel savings compared to forced-air unit heaters made this investment very attractive for Sheffield, especially since most Space-Ray customers were averaging over 30% more fuel efficiency than forced-air units along with a corresponding savings of up to 50% on their monthly fuel bills.

Service Shop Described

Sheffield's 6,000 sq. ft (60 x 100) service area includes 14 service bays. The building consists of a metal roof structure, with the walls and roof insulated with 3 " fiberglass insulation. Each bay has access to one of fourteen 12 x 12 metal doors; 3" fiberglass insulation on each of the doors helps reduce the building's heat loss.

The three Space-Ray RSTP 17-L5 radiant LP heaters were installed on beams 16' from the concrete slab floor. They are aimed directly toward the bay areas, providing a comfortable heated environment averaging 65° F.

Because the heaters were installed according to Space-Ray recommended clearances for combustibles, Sheffield noted that there has been no problem with car paint exposed to radiant heat or cars being directly under the heaters.

Other Building Has Conventional Units

As a result of the installation and based on data from an adjacent building which Sheffield rents out, he feels confident that he has made the right choice.

"I also own a lot next to mine which I rent to a recreational vehicle dealership," Sheffield noted. "They were seeking a heating system for their metal building at about the same time I was. Instead of installing a radiant heating system, they decided to install three forced-air gas unit heaters in their service area, each with a rating of 250,000 Btu/hr."

Compared to Sheffield's 60 x 100 service area, the recreational vehicle dealership has a service area of 70 x 75. It also has only three 12 x 16 service doors compared to Sheffield's 14 doors of the same size.

According to Parker, whose gas distributorship sells LP propane gas to both dealers, fuel consumption for the Space-Ray units was 30-40% less than the forced-air unit heaters used by the recreational vehicle dealership.

Other Units Added

Based on his experience, Sheffield has already recommended Space-Ray heaters to several other area GM dealerships. In addition, Sheffield has also added eight more Space-Ray units to his dealerships.

Case Study: A QUARTER MILLON DOLLARS SAVED BY LEVI STRAUSS DISTRIBUTION CENTER

"We were barely maintaining a temperature of 60 degrees," noted Gary Cooper, maintenance manager of the company's Florence distribution center. "Employees had to wear sweaters and jackets to keep warm, a real problem during sub-zero winter temperatures. Complaints were frequent, morale was low and productivity was affected."

After a search including a heat analysis process with five major heating unit manufacturers, Cooper and Levi Strauss decided that heating and comfort needs could best be met by replacing the unit heaters with 28 RSTP17 infrared gas-fired radiant tube heaters from the Space-Ray Division of Gas-Fired Products, Inc., Charlotte, NC. The heaters were placed five ft down from the 24 ft high ceiling replacing 20 forced air units.

Since installing the system, employee complaints have stopped and Levi Strauss has saved over a quarter million dollars in gas and electricity costs alone during five heating seasons.

"I stuck out my neck going with Space-Ray's radiant heat technology," Cooper recalled. "The technology was relatively unknown to our corporate management who seemed to be more comfortable at that time with the forced air heating units. That's all changed now. If I propose adding gas-fired radiant heaters to any part of my facility now, it is much easier to justify."

The units operated so efficiently and cost-effectively that additional forced air units were replaced in the facility's shipping and receiving area and in the shipping area of an adjoining 116,000 sq. ft reserve warehouse that is similar in structure to the active warehouse. These units also replaced forced air units.

"These heaters will probably save us a half million dollars by 1992 in heating and electricity costs depending on the severity of the winter," Cooper said. "If building usage changes, we can relocate the heaters. They are among the most reliable and flexible I have seen. We are obviously extremely pleased."

"The forced air units were not efficient at all," Cooper noted. "Employees were cold and we couldn't adjust the units or move them for maximum comfort. They were stationary and totally non-flexible. Also, instead of wearing sweaters and jackets, as with the former units, our employees are now wearing short sleeve shirts, even in the winter," Cooper noted. "I don't have any more employee complaints, morale is up and productivity has increased. "

For optimum savings and efficiency, the tube heaters are controlled by a Honeywell Energy Management System from Friday at midnight to 4 A.M. Monday, but temperatures are never allowed to fall below 55° F.

"We turn the system on Monday at 4 A.M. so that the temperature reaches 70 degrees by the time the first shift arrives at 6 A.M.," noted Cooper. "During the week, we turn the system on at 5 A.M."

According to Cooper, in the five years of operation in the 192,000 sq. ft building, the infrared gas-fired radiant tube heaters have never had a maintenance problem. "I negotiated a spare parts package, but haven't needed to use it," Cooper said. "Performance has been superior. The only maintenance required was dusting the units each year."

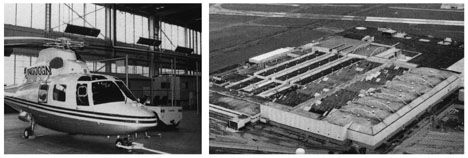

Case Study: AIRCRAFT REPAIR FACILITY SAVES UP TO $800,000 ANUALLY

An interior view of the main 450 by 800 foot long aircraft hangar of Topflight Airpark, showing the position of some of the 117 Space-Ray RSTP17 gas-fired tube heaters in the 50 to 70 foot high hangar utilizing Space-Ray's perimeter heating design, 60% of the tube heaters were mounted on the on the perimeter about 35 feet above the floor, with the remaining 40% mounted about 60 feet above the floor next to the catwalks.

HAGERSTOWN, Maryland - Tom Allgyer, President of Topflight Airpark, admitted that upgrading the heating system in the former Fairchild Industries aircraft maintenance and manufacturing plant to infrared heating was an excellent choice. Since deciding to replace three large oil-fired boilers with a total of 259 infrared heaters from the Space-Ray Division of Gas-Fired Products, Inc., Charlotte, NC, Topflight has obtained substantial fuel savings and a return investment in well under a year.

Records at the plant indicate that heating costs with the old boiler system ranged between $700,000 and $1,000,000 a year, not including the cost of steam used in the production process. "With the Space-Ray heaters, energy costs have been ranging between $135,000 to $200,000 a year, depending on the severity of the winter," Allgyer said. "Return on investment was achieved well within the first year and heating comfort is much more uniform. The result is a more comfortable and productive working environment."

This equates to energy savings of $565,000 to $800,000 a year and reduction in annual fuel consumption by over 70%.

Conversion to Space-Ray Heaters

Located adjacent to the Washington County Regional Airport in Hagerstown, the former Fairchild Industries plant was converted from what was primarily an aircraft assembly line into mainly aircraft maintenance hangars, some warehouse space and office space.

Built in 1940 and expanded in the early 1950's, the over 1,000,000 sq. ft complex has a combination of flat and pitched roofing with glass windows on some of the exterior walls and various large access doors. To heat the complex, Fairchild Industries used three large oil-fired boilers. "Our first priority was to replace the old system with a more efficient and economical heating system," Allyger noted. "With the boilers, heat distribution was not uniform and the systems, in our opinion, were too noisy, dirty and inefficient, especially during the cold winter months." Allgyer contacted a representative of Space-Ray who analyzed the facility and its heating patterns. Using Space-Ray's free COMPUHEAT® computerized heat loss analysis, Space-Ray determined that by using radiant heat technology, Topflight's annual savings in energy costs could be tremendous and would result in at least an annual fuel reduction of 50%.

For Topflight, Space-Ray specified a total of 209 RSTP17 gas-fired infrared tube heaters, each with a 175,000 BTU/hr capacity, 40 LTU75 unitized low intensity infrared tube heaters, each with a 75,000 BTU/hr capacity, and four LTU60 unitized low intensity infrared tube heaters each with 60,000 BTU/hr capacity. The capacity of the total system is 40,265,000 BTU/hr. Because natural gas is directly available from the nearby pipeline, this fuel source was used for added economy.

Buildings Described

The Topflight complex consists of a 450 ft by 800 ft aircraft hangar and industrial building, a 250 ft by 350 ft Executive Aircraft Hangar, a small 74 ft by 100 ft aircraft hangar used by the Army Reserve to maintain helicopters and a large warehouse structure with six bays, each of which is approximately 45,000 sq. ft.

Executive Aircraft Hangar (250'x 350') of the Topflight Airpark facility with three large 46 foot high doors. Overall view of the 1,000,000 square foot concrete block and steel Topflight Airpark complex in Hagerstown, Maryland.

The three large buildings are interlinked, with the small aircraft hangar the only separate stand-alone structure. One section of the 450 ft by 800 ft building has 70 ft high ceilings and three large 46 ft high doors along the entire width of the building. Major tenants include J&W Corporation which maintains aircraft as large as a Boeing 727 and 737, and a manufacturer of modular commercial buildings. A second building, the Executive Aircraft Hangar, is 250 ft by 350 ft with 50 ft ceilings. One side of the building is all glass, with the other side consisting of doors with large glass windows. In the warehouse structure, each of the six rental bays is separated by concrete block walls. Two of the bays have 16 ft ceilings. Truck-size doors open and close as necessary. Tenants include Maryland Air Industries, a local Coca-Cola distributor, a record and tape distributor and the U.S. Government. The total number of individuals working in the Topflight complex exceeds 500, with many working in shifts.

Perimeter Heating Layout Detailed

In the main 450 by 800 ft aircraft hangar a perimeter design proven efficient in many other large aircraft installations heated by Space-Ray was used. Approximately 60% of the tube heaters on the perimeter were mounted about 35 ft. above the floor, with the remaining 40% mounted 60 ft. above the floor next to the catwalks.

Installation was simple since Space-Ray heaters are unitized and factory shipped as complete units, with only a few bolts usually necessary for mounting. All areas were also designed with individualized temperature controls for efficiency and heating comfort.

In the Executive Aircraft Hangar, a total of 35 RSTP17 heaters and four LTU75 heaters were installed. For the Army Reserve structure, six RSTP17 heaters were used on one perimeter and eight on the other perimeter.

"In three heating seasons, we have not experienced any major service problems with the heaters," AlIgyer emphasized. "We are extremely satisfied with the units, especially with their clean, efficient and quiet operation."

"We are extremely pleased with how efficiently and effectively this mega-facility is now being heated," noted Bob Genisol, VP Sales and Marketing of Space-Ray. "Annual energy savings of $565,000 to $800,00 is quite impressive. The savings, coupled with heating comfort achieved, speaks for the quality and efficiency behind the Space-Ray tube heaters."

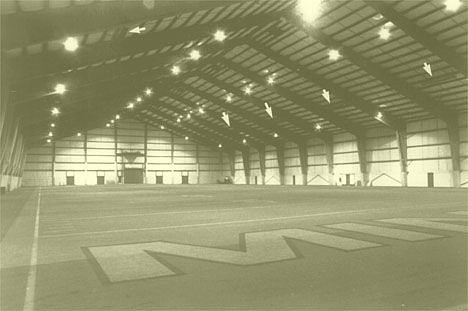

Case Study: SPACE-RAY INFRARED IDEAL FOR INDOOR FOOTBALL PRACTICE FIELD

After consecutive 3-8 and 1-10 records, it was time for the University of Minnesota "Gophers" to do something to improve their prospects before the next football season.

First on the agenda was hiring a new coach. The University hired Lou Holtz from the University of Arkansas Fayetteville. Aware of Minnesota's cold and unpredictable weather, Holtz convinced the University administration that the team needed an indoor practice facility.

His efforts yielded a 75,000 sq-ft, metal-enclosed, two-story structure supplied by Chief Industries Building Division, Grand Island, NB.

The indoor facility was designed with a 194 ft. x 384 ft. clearspan, 57 ft. high at the peak. RSTP-17 radiant gas tube heaters, each with 175,000 Btu/hr capacity, from the Space-Ray division of Gas-Fired Products, Charlotte, NC, are mounted horizontally on trusses, approximately 45 ft. from the outside walls on either side of the V-shaped roof and 32 ft. from the floor. There are six on each side, evenly spaced throughout the 194 ft. long facility.

Axel Newman Heating and Plumbing, one of the Newman Companies of St. Paul, MN, was the mechanical contractor on the job. The contractor specified the infrared heaters and purchased them from Associated Representatives, Inc., Bloomington, MN.

According to Richard J. Cowan, vice president of Associated Representatives, the practice facility is one of, if not the only, indoor football facility in the U.S. with radiant gas tube heaters.

Although most of the university was heated by a central steam plant, the location of the new facility made it impractical and uneconomical to link it to that facility. As an alternative, the radiant gas tube heaters were chosen.

A hot water boiler system was installed to heat other parts of the new sports complex which, in addition to the practice field, includes a two-story structure with full basement for offices, locker rooms, a sauna, steam room, and weight-lifting facility.

Construction on the building began in May, 1984, and was completed by the end of September, in time for the Big Ten season.

For insulation, 6 in. blankets on the roof and 4 in. vinyl - reinforced blankets on the sidewalls provide an R-value of 20 and 9, respectively.

Because the structure does not incorporate skylights or windows, a sophisticated ventilation system also was included.

The Space-Ray heaters were mounted on trusses approximately 45 ft. from the outside walls on either side of the V-shaped roof, 32 ft. from the floor. They were mounted horizontally, six on each side, evenly spaced throughout the 194 ft. long practice field.

Each heater is protected by wire mesh fastened to it and secured to the truss. Each series of heaters also has its own thermostatic controls to produce an environment up to 68°F.

According to Bruce Lothson, project manager for Axel Newman, Space-Ray was specified because of price, and also for installation ease, because the heaters were pre-assembled by the manufacturer.

Lothson said that, for the first month, the university heated the facility 24 hours a day at a constant 68°F.

"This proved impractical as well as expensive because the facility was not used all day," Lothson said. "Instead, two hours before practice the heaters are turned up to produce the desired temperature."

Holger Christiansen, athletic field coordinator, said coaches and players were extremely pleased with the facility and the heated environment.

"Heaters now are set at 40°F during the winter, which is comfortable for winter- conditioning drills," Christiansen said.

The team's record for the next season improved to 4 - 7.

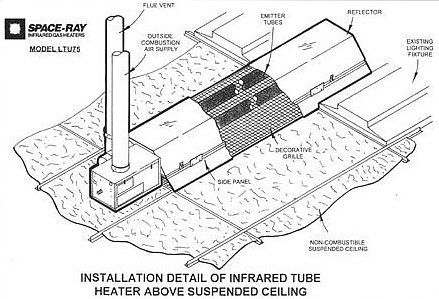

Case Study: AUTO DEALERSHIP SERVICE AREA

CHARLOTTE, NC - Four unitized, low-intensity gas-fired infrared tube heaters from Space-Ray of Charlotte, North Carolina, have helped a Buick-Subaru dealer located here renovate and upgrade its service write-up area by creating a warmer, more friendly and comfortable atmosphere in which they receive their service customers.

The four LTU75 tube heaters, each with a 75,000 Btu/hr capacity, are mounted horizontally above the suspended ceiling and recessed above decorative grilles out of view of customers in the service area of Charlotte, North Carolina-based Folger Buick-Subaru.

Two heaters each are placed in the front and back of the aesthetically appealing, customer-friendly 30 ft. wide by 60 ft. long service area between one of four service consultant stations and the 12 ft. wide by 14 ft. high roll-up steel doors. Each pair of two heaters is controlled by a Space-Ray Setback 2000 thermostat, with temperatures set at 68° F. The four Space-Ray LTU75 infrared tube heaters are mounted horizontally above the suspended ceiling and recessed above the decorative grilles out of view of customers in the service write-up area.The heaters normally operate from October to March.

Before the renovation, Folger service customers had to drive through the large, noisy general mechanic bay area. The service write-up bays were heated with forced air heaters which made it cold and uncomfortable for service drive-through customers during cooler temperatures.

Perry Stokes, Folger's Director of Service and Parts, reported that the service atmosphere improved which not only benefits customers but his service reps as well. "Before, the customer entered the general bay area in full view of the mechanics and with noise created by the tools of the trade," Stokes said. "It was also cold since we didn't have heaters directly over the drive-through area."

He added that the atmosphere now is like night and day. "We have been very pleased with the quietness of the unit's operation as well as its efficiency in heating objects and bodies first instead of just heating the air as do forced air heaters," he said. "In fact, they are so quiet most of our customers probably don't even know they are there. The area is warm and the atmosphere is friendly and quieter. This allows us to concentrate first and foremost on our customers' needs."

Case Study: CHRYSLER PARTS DISTRIBUTION CENTER SAVES 50% OR MORE

MANSFIELD, MA. A perimeter design using gas-fired infrared heaters from Space-Ray, Charlotte, NC, has resulted in significantly lower annual fuel costs for a large automotive parts distribution center located in Mansfield, MA. According to figures provided by the Chrysler Corporation and the natural gas supplier, Bay State Gas Company, the average fuel costs for the 215,000 square foot warehouse and office complex are approximately 12 cents per square foot, a savings of 8 to 13 cents or up to 50% or more when compared to heating costs for a similar type warehouse in the area. Total annual energy costs are between $26,635 to $28,302 a year.

The Space-Ray heating system was installed in the newly-constructed 336 foot by 576 foot Chrysler Corporation warehouse, training and parts facility in 1989. The perimeter design consists of 28 infrared heaters strategically placed in the large warehouse structure. Instead of one temperature control for the whole system, the Space-Ray system was designed with individual controls for groups of up to three heaters for maximum zone comfort.

To heat the new warehouse, Terry Condon, President of the Condon Company, specified a total of eight RSTP17 vented gas-fired infrared heaters, each with a 175,000 Btu/hr capacity; three RSTP10 infrared tube heaters, each with a 100,000 Btu/hr capacity; and 14 LTU-75 unitized low intensity infrared tube heaters, each with a 75,000 Btu/hr capacity. Total capacity of the entire warehouse heating system was 2,750,000 Btu/hr. According to Condon, this is 40 percent less input than a comparable system to do the same job.

Space-Ray's free and unique COMPUHEAT® computerized heat loss analysis was conducted before installation of the system to determine optimum heater selection and approximate fuel cost.

Building Described

The Mansfield facility is a concrete slab structure with standard membrane type roof construction. It consists of concrete walls with up to 2.5 inches of insulation and metal deck roof. The facility has 18 loading dock doors that are from 12 to 16 feet high and 10 to 12 feet wide.

"The client became interested in infrared gas heaters based on results we achieved at the nearby Nissan Motor Corporation auto parts facility we built in the same office complex and outfitted with a competitive gas fired radiant heating system three years earlier," noted Condon. "Chrysler insisted on an infrared radiant gas heating system and wanted us to not only update ourselves on the systems available but recommend the most economic system available for their plant."

Condon noted that Chrysler eventually chose the Space-Ray system over competitive systems because of its simpler design, higher radiant efficiency, minimum maintenance and lower first cost.

"None of us knew that Space-Ray would be that much more superior to the previous system we used," Condon noted. "We were used to seeing a tail pipe along the building perimeter and questioned Space-Ray on the efficiency of their system when we found that this was not included."

Perimeter Heating System

Space Ray's infrared heaters were mounted 5 feet from the loading dock doors and hung from steel trusses four feet from the 33 foot high ceiling. All were mounted at 15° angles for maximum warmth and comfort.

Condon noted that the Space-Ray heaters were easier to install and maintain compared to the competitive system he used previously which was not unitized.

"With the other system, if one of the unit's vacuum pumps became defective, the whole system shut down. This was not the case with Space-Ray where a defective unit will not cause the whole system to shut down. Installation was simple since all Space-Ray heaters are unitized and factory shipped as complete units, with only a few bolts usually necessary for mounting."

The cost of the Space-Ray system was 40 to 50 percent less than the competitive system he previously recommended. Once installed and considering labor cost, actual savings increased to over 50% compared to the competitive system, Condon observed.

Based on four years heating experience, the system has also proved to be more efficient. The input firing range of the Space-Ray system averages 16 BTU/sq. ft compared to 25 to 30 BTU/sq. ft for conventional heating systems. "Considering that we need about 40% less Btu/hr input to begin with to maintain the same heating comfort, annual savings with this feature is significant."

Condon also noted that the client feels that the comfort level of the Space-Ray system is much more efficient than other systems they are familiar with. "They are very pleased with the uniform heating coverage provided by the Space-Ray system. Optimum warmth and comfort has been maintained for the employees during the past four winter heating seasons."

Kevin Kelley, Maintenance Supervisor for Chrysler Corporation, was concerned when they first moved into the building. "He was concerned because the previous building was so uncomfortable, and was sure the small number of Space-Ray units would not heat the warehouse," Condon said. "He became pleasantly surprised and pleased with the comfort throughout the building once the heaters were installed from end to end and side to side. Even between the racks, the temperature was consistent. Not only that, but Chrysler has not experienced any service problems with the heaters in four heating seasons."

Condon added that Chrysler is extremely satisfied with the units and their clean, efficient and quiet operation. "We are currently specifying a Space-Ray system for another Chrysler warehouse facility."

Case Study: BOILER-TO-GAS INFRARED CONVERSION RESULTS IN LESS THAN ONE-YEAR PAYBACK FOR COLORADO STEEL PLANT

PUEBLO, Colorado - When CF&I Steel Corporation looked into replacing its 30 year-old steam heating system in three auxiliary operations within its Pueblo, Colorado steel plant, a quality circle group from the boiler shop area consisting of management and bargaining unit employees had the task of determining the feasibility of either repairing or upgrading the old system, installing a new system, or installing an alternate energy system.

CF&I Steel Corporation's Pueblo Plant produces over 500,000 tons a year of rails, seamless tubes, rod bar and wire products for shipment throughout the United States.  It has two 150-ton electric furnaces and two continuous casters. There are also rail, bar, rod, wire, seamless tube and other mills, a casting foundry and various auxiliary operations.

It has two 150-ton electric furnaces and two continuous casters. There are also rail, bar, rod, wire, seamless tube and other mills, a casting foundry and various auxiliary operations.

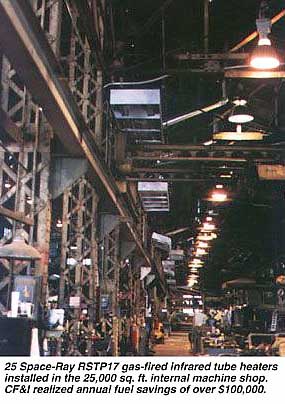

In its energy evaluation, CF&I's quality committee analyzed steam heating systems for the 25,000 sq. ft internal machine shop, a 5,035 sq. ft pipe shop and a 10,750-sq.-ft weld shop. The three buildings were erected in 1910 and consisted of uninsulated metal and brick and flat metal deck roofs.

According to Walt Walker, Combustion Engineer at CF&I in Pueblo, it was found that the cost of replacing old pipes going into these three buildings from huge boilers located within the CF&I plant complex would be tremendous.

"The boilers and pipes were found to be terribly inefficient and resulted in a heat loss of 4,000,000 Btu's in the machine shop alone," Walker noted. "It wasn't a closed loop central heating system and consisted of steam being piped into insulated radiators and fans located above the floor in the three facilities. Heating was also uneven and did not provide an adequate employee comfort level. The employees in three buildings were always cold since inside temperatures averaged only 40°F during the Fall and Winter heating season. Most of the employees had to wear layers of clothes and warm insulated jackets just to keep warm. Complaints were frequent."

After eliminating the boiler option, the quality circle looked at various natural gas systems including forced air heat, unit heaters and radiant infrared heaters.

After evaluating the various presentations, the quality circle members and Walker installed 35 RSTP17 gas-fired infrared tube heaters from the Space-Ray Division of Gas-Fired Products, Inc., Charlotte, NC, in three shop units. Each unit has a capacity of 175,000 Btu's. In addition, Walker also decided to purchase six Space-Ray RSPA5C radiant broad area heaters for the pipe shop, each with 50,000 Btu output.

According to Walker, during the first heating season, CF&I saved over $100,000, with estimated savings for the next heating season expected to be $130,000. He said payback for the system was in less than a year. "Btu savings are tremendous and heating efficiency optimum, considering the age of the three buildings," he said.

Installation Described

Of the 175,000 Btu Space-Ray RSTP17, gas-fired infrared tube heaters, 25 were installed in the machine shop, eight in the weld shop and two in the pipe shop. Total heat losses for different buildings were 4.85 million Btu/hr for the machine shop, 1.75 million Btu/hr for the weld shop and 650,000 Btu/hr for the pipe shop.

The machine shop consists of an uninsulated "A-Frame" type metal and brick building with a 30-foot-high center section and two parallel 18 foot high bays on either side. The building is 100 feet wide by 250 feet long. The top part of the center section and lower part of the two bays consist of numerous glass windows. Two large sliding metal doors on tracks are also located on both ends of the building for product and equipment transportation.

Most of the employees in the building work around stationary equipment such as lathes, allowing heaters to be adjusted toward the work station for optimum heating efficiency and employee comfort and welfare. Walker added that since installation of the heaters, employee complaints have been greatly reduced.

"Our heating season is from October to April with average temperatures during the winter months of about 30°F for this time period," Walker noted. "Temperatures get down to 10° below zero at times. Instead of wearing layers of clothes, employees now work in more comfortable clothing. With uniform, consistent heat, they are definitely a lot more comfortable and I feel that the heaters have also increased their morale and productivity," said Walker.

"With the temperature differential caused by the old steam heating system, the building actually sweated and caused rusting of the structure," he said. "We avoided this by venting the units."

Unlike the machine shop, the weld shop is 215 feet long by 50 feet wide and the pipe shop 47.5 feet wide and 106 long. Ceiling height in the weld shop is 30 feet and 17 feet in the pipe shop. Both buildings have glass windows on both sides.

CF&I Extremely Pleased With Heaters

Walker said that the even heat distribution of the tube heaters is a key factor in influencing CF&I's decision to install additional Space-Ray heaters in the future at other locations within the Pueblo plant complex.

Walker added that with the Space-Ray units, maintenance at CF&I has also been significantly reduced.

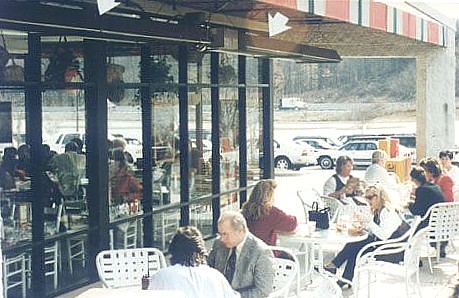

Case Study: OUTDOOR RESTAURANT HEATING INCREASES OUTDOOR SEATING CAPACITY AND PROFITABILITY

GASTONIA, NC -- Just as restaurants in Arizona use misters on their patios to cool their customers during the hottest months of the year, two unitized, low-intensity gas-fired infrared tube heaters from Space-Ray of Charlotte, NC, are now helping a Hickory Hams restaurant in Gastonia, NC increase its seating capacity by 40 percent during cooler months by creating a warm, comfortable atmosphere for patrons to enjoy their meals on the restaurant's patio. Seating capacity at the restaurant has increased from 75 to 111 during cooler weather, allowing on-time seating with minimum waiting.

The two LTU90 infrared tube heaters, each with a 90,000 Btu/hr capacity, are mounted horizontally and end-to-end above the outside eating area in view of the customers. The heaters are normally used during the cooler months from October to March and can be manually adjusted to the desired temperature which averages 68° Fahrenheit.

Unlike other open-surface combustion heating systems available for patio applications, Space-Ray's LTU series heaters are not affected by outdoor environmental conditions. Since the flame is totally enclosed in the combustion chamber, strong gusts of wind do not affect the operation of the heater.

Marion H. Davis, Jr., president of Hickory Hams, said he decided to purchase the Space-Ray heaters for his patio to better serve his customers and increase business. He said that before the heaters were installed, the restaurant's patio was completely useless when it was cold outside. Davis also pointed out that on several occasions he couldn't accommodate all the people who wanted to dine at his restaurant.

"Our sales potential was really affected during cooler months because our outside eating area seats 36 people.  Now when it's cool outside and the heaters are on, often times we fill up the patio before the inside area which seats 75," he said. "Customers are amazed at how warm they are under the heaters when it's 30° Fahrenheit outside

Now when it's cool outside and the heaters are on, often times we fill up the patio before the inside area which seats 75," he said. "Customers are amazed at how warm they are under the heaters when it's 30° Fahrenheit outside

Another advantage to having the LTU90 tube heaters on the patio is the fact that since they are placed near the windows of the restaurant, infrared heat is transmitted through the windows which helps heat that side of the eating area. "In the cooler months I don't even have to run the heat on that side of the building because the Space-Ray heaters do the job from the outside," Davis noted. "That reduces my electric bill and produces a more uniform heat throughout the restaurant. I have definitely already gotten a return on my investment. We are also constantly getting compliments from our customers about the comfort of the patio eating area during cool weather," he added

"Hickory Ham's customers are amazed at how toasty they are outside when it's cold," noted Bob Genisol, Space-Ray's Vice President of Sales and Marketing. "They also comment on how quiet the heaters are when they're on. They help create a very unique and enjoyable eating experience.

Other area eating establishments where Space-Ray equipment can be found include Pop's Restaurant in Durham, NC, and Stockcar Cafe in Cornelius, NC.

Perry Stokes, Folger's Director of Service and Parts, reported that the service atmosphere improved which not only benefits customers but his service reps as well. "Before, the customer entered the general bay area in full view of the mechanics and with noise created by the tools of the trade," Stokes said. "It was also cold since we didn't have heaters directly over the drive-through area."

He added that the atmosphere now is like night and day. "We have been very pleased with the quietness of the unit's operation as well as its efficiency in heating objects and bodies first instead of just heating the air as do forced air heaters," he said. "In fact, they are so quiet most of our customers probably don't even know they are there. The area is warm and the atmosphere is friendly and quieter. This allows us to concentrate first and foremost on our customers' needs."